Why Revive's Inventory Module?

At a time when customers need products faster, supply chains are more spread out than ever, and businesses need to be leaner, having knowledge and control over your inventory is essential to your business’ success.

Make shortages a thing of the past, connect your warehouse to the rest of your business in real-time, and streamline your inventory receipts and disbursements.

Revive’s user-friendly inventory module integrates seamlessly with your warehouse operations, ensures that information is recorded easily, immediately, and accurately, and alerts you when potential issues arise, so your business never has to slow down.

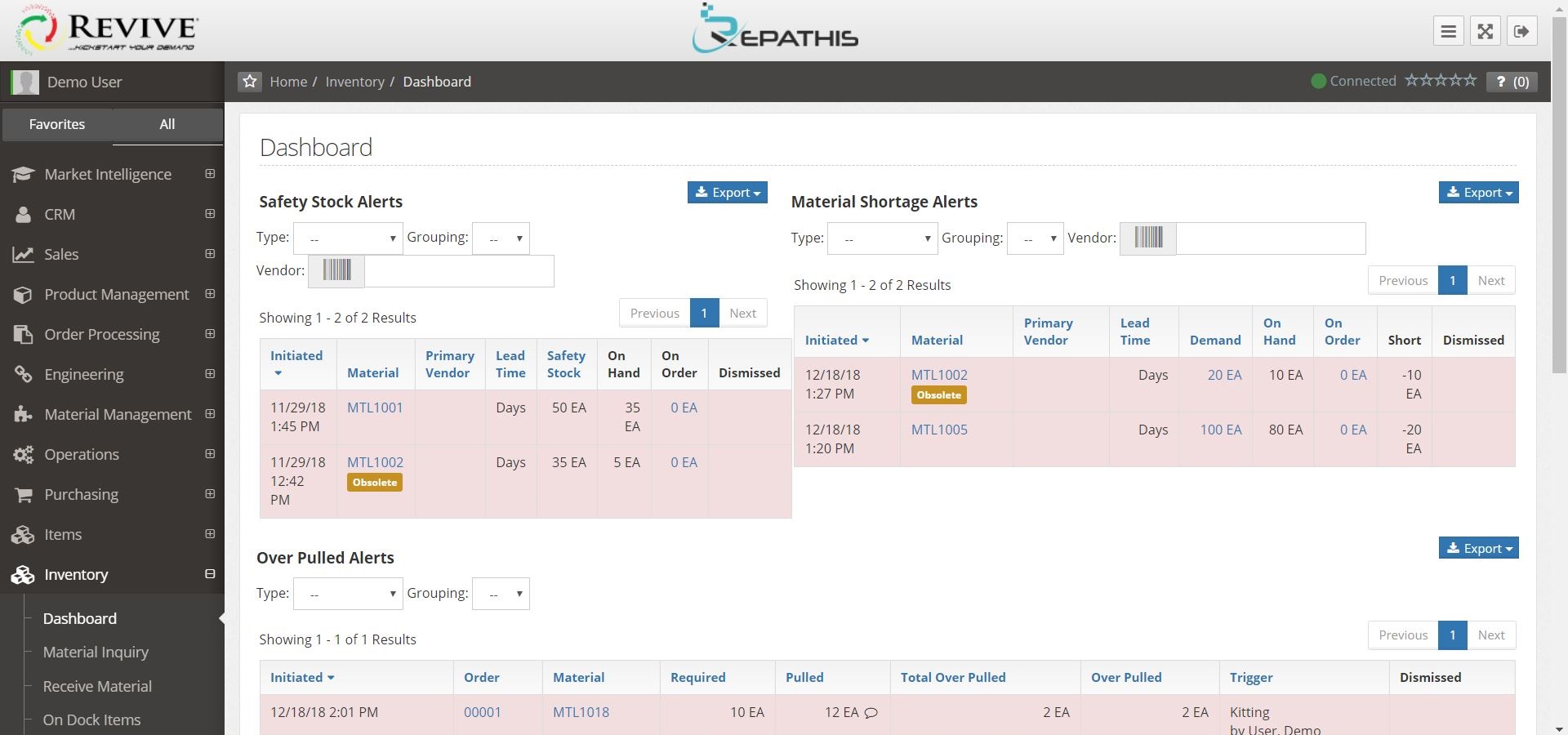

DASHBOARD

Material shortage alerts, safety stock alerts, and over-pulled alerts make sure that you are immediately made aware of any potential issues that arise. With real-time alerts, you can say goodbye to shortages, and have peace of mind that your business is running safely and efficiently.

- Material Shortage Alerts

- Safety Stock Alerts

- Over Pulled Alerts

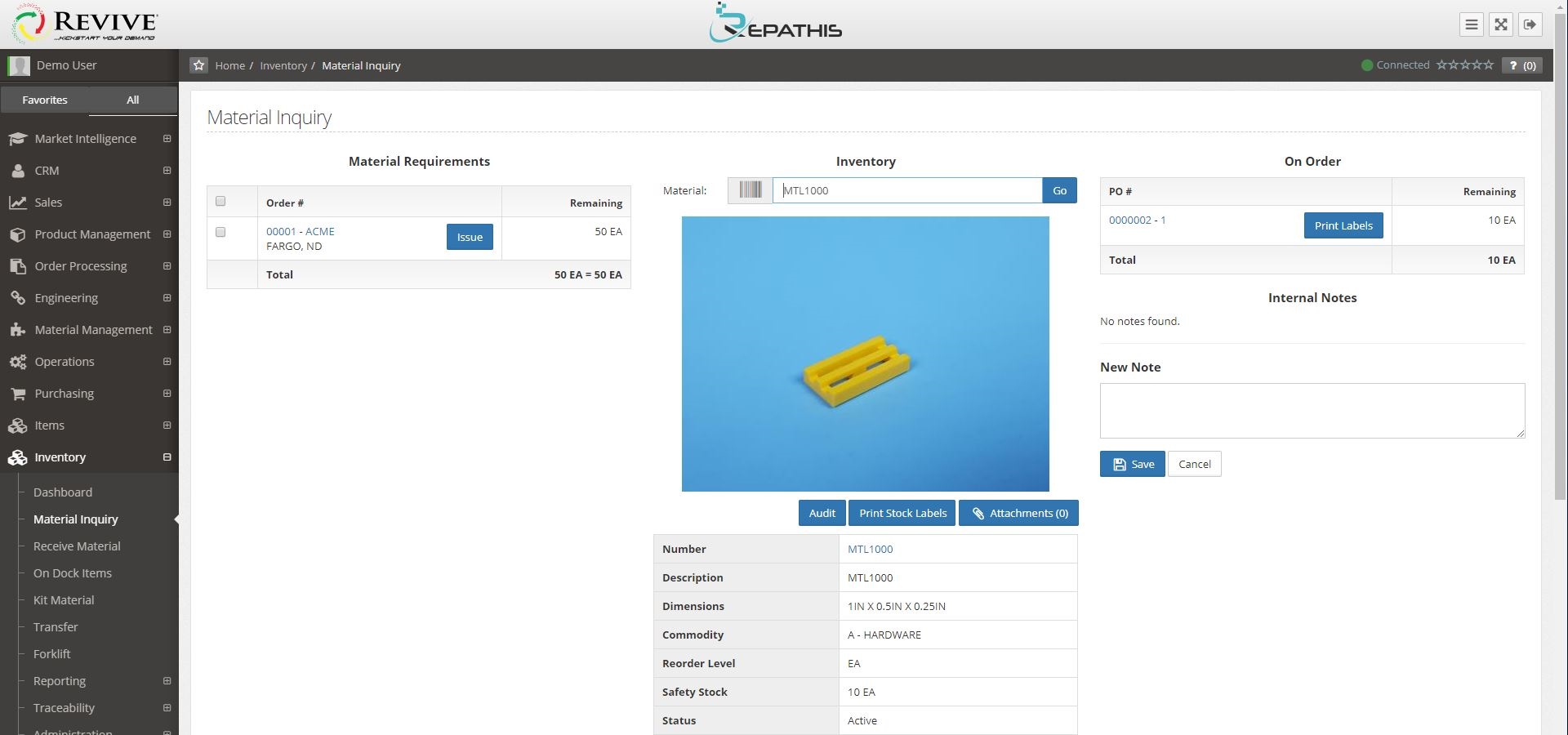

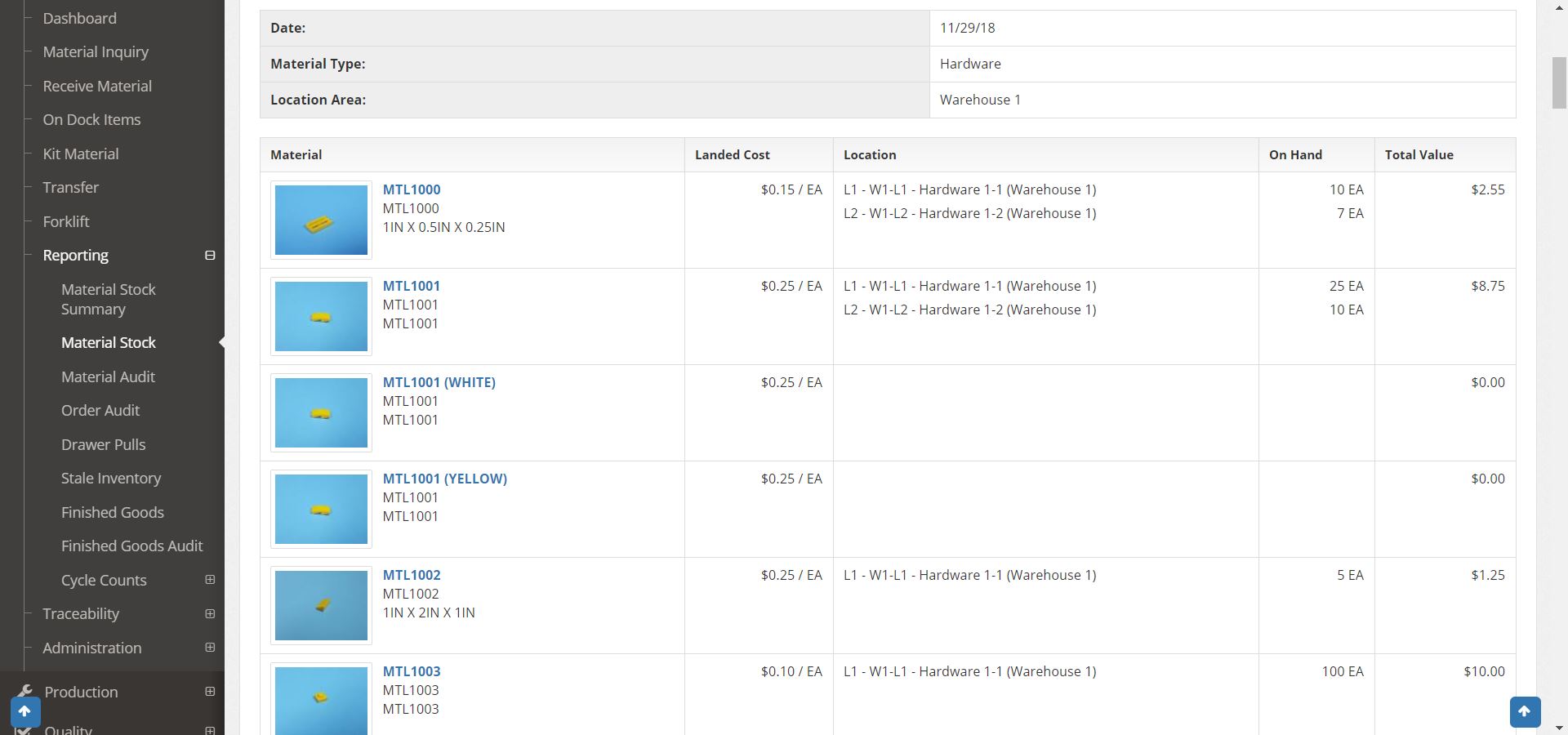

ITEM INQUIRY

Have access to up-to-date material information at your fingertips. No more sifting through Excel spreadsheets or worrying about accuracies. Simplify your analysis, so you can know exactly how much material you need, how much you have, where you have it, and how much is on order.

- On Hand

- Current Demand

- On Order

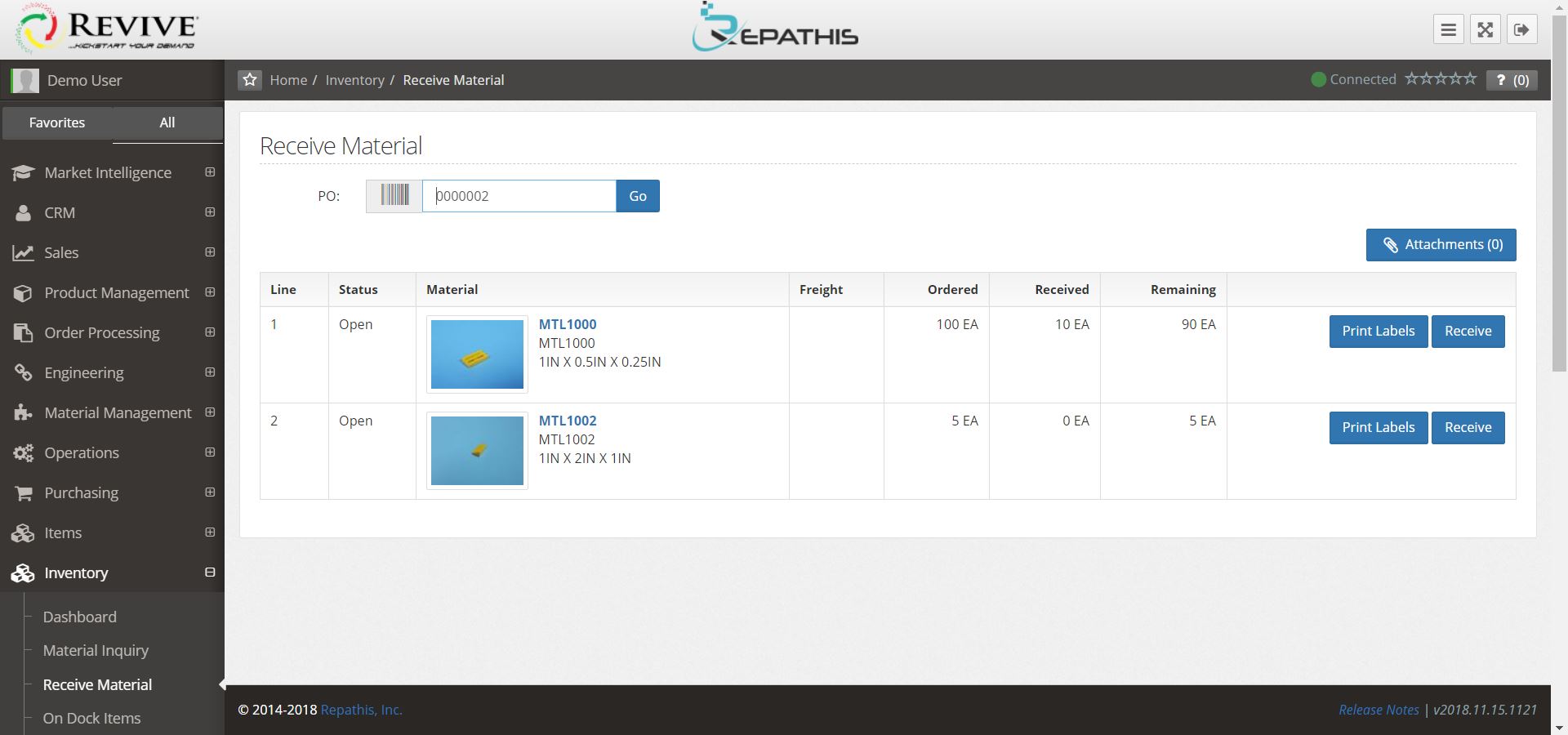

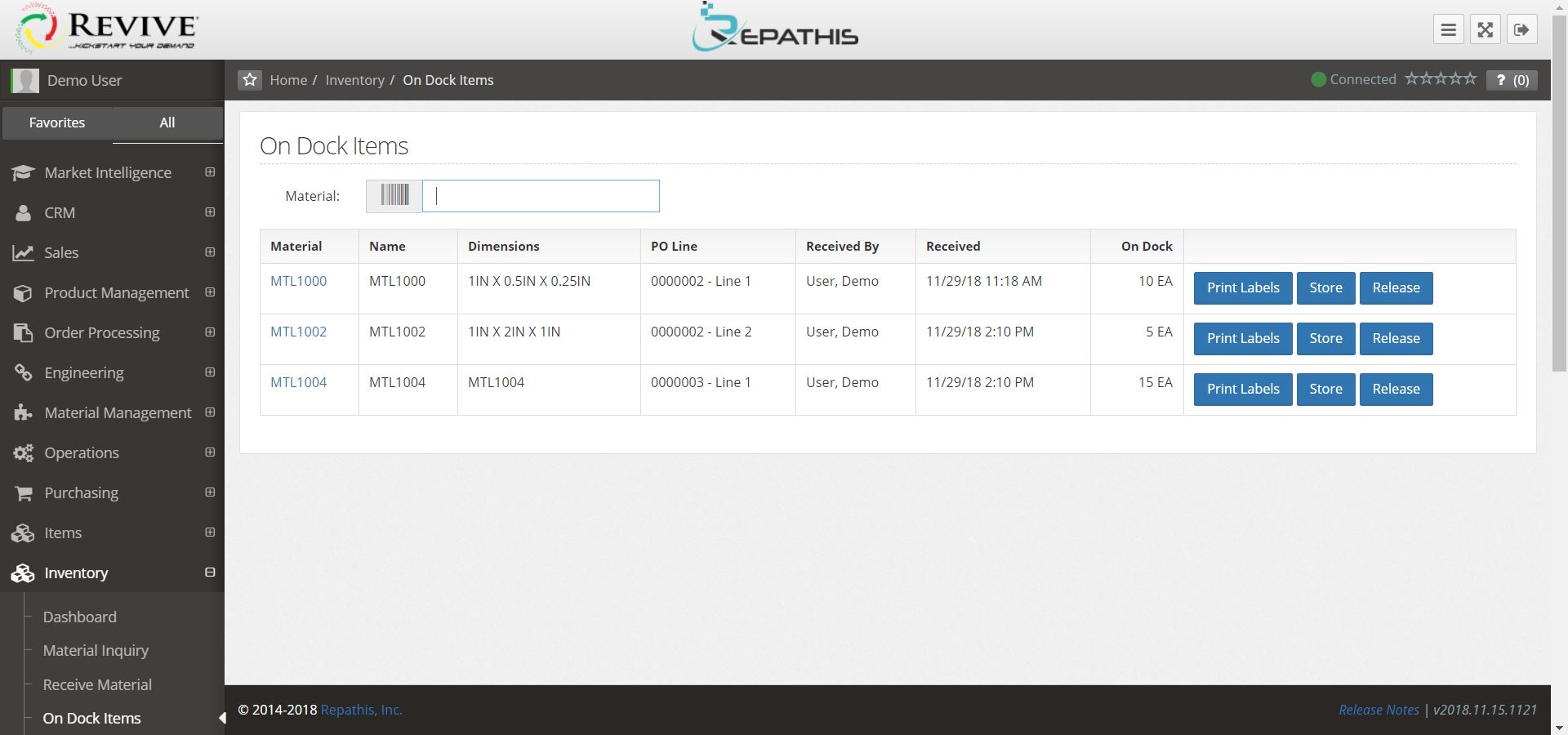

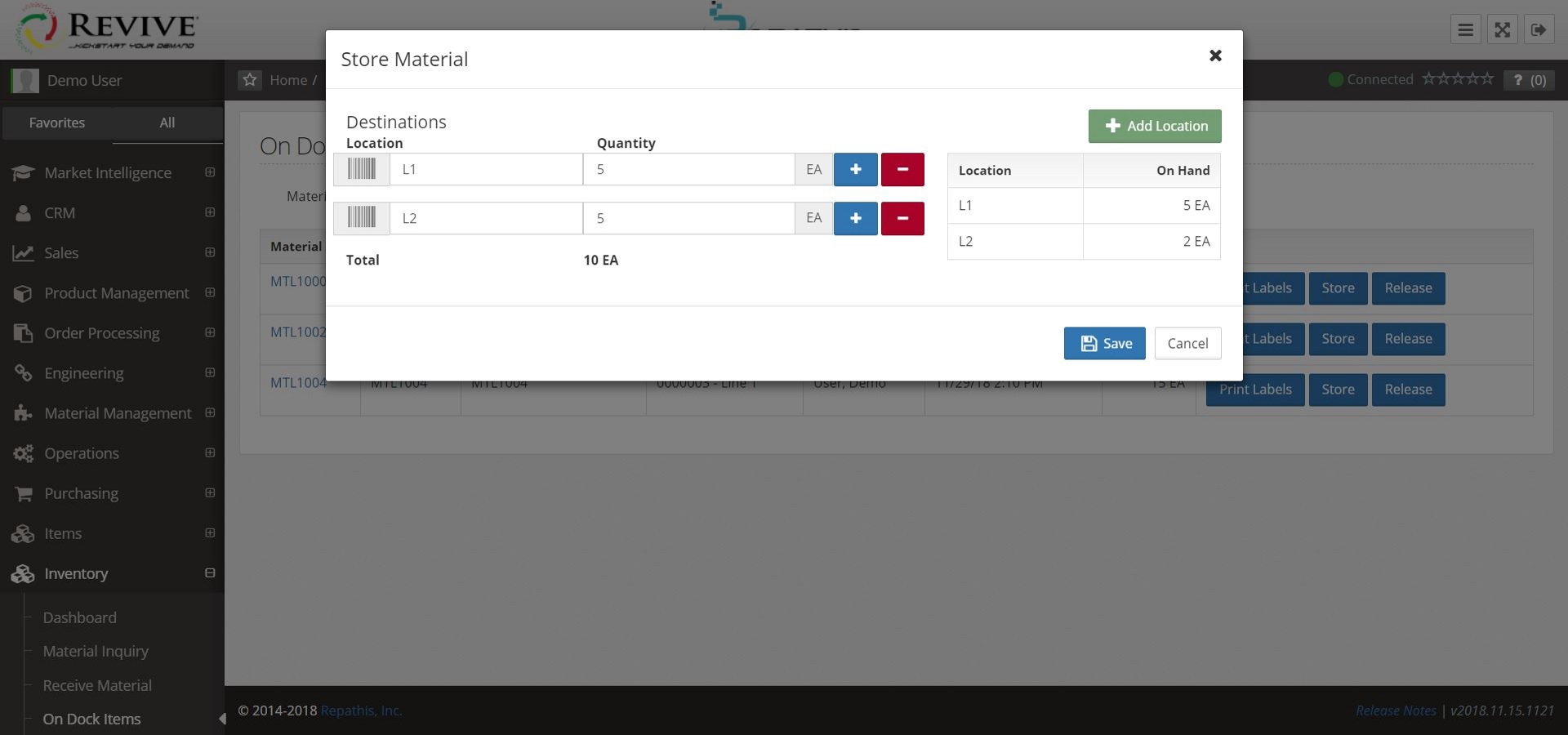

RECEIVING & STAGING

Streamline your receiving and staging processes while tracking every item received. Items can be received directly against an issued PO, ensuring accuracy of records and communication between departments. Keep your inventory and records organized and precise by printing and attaching labels as items are received, and then scan to store in specific inventory locations.

- Receive directly against an issued PO

- Print and attach labels as items are received

- Quickly receive to an On Dock/Staging Area for later handling

- Store items to specific inventory locations

- Release back to PO in case of error

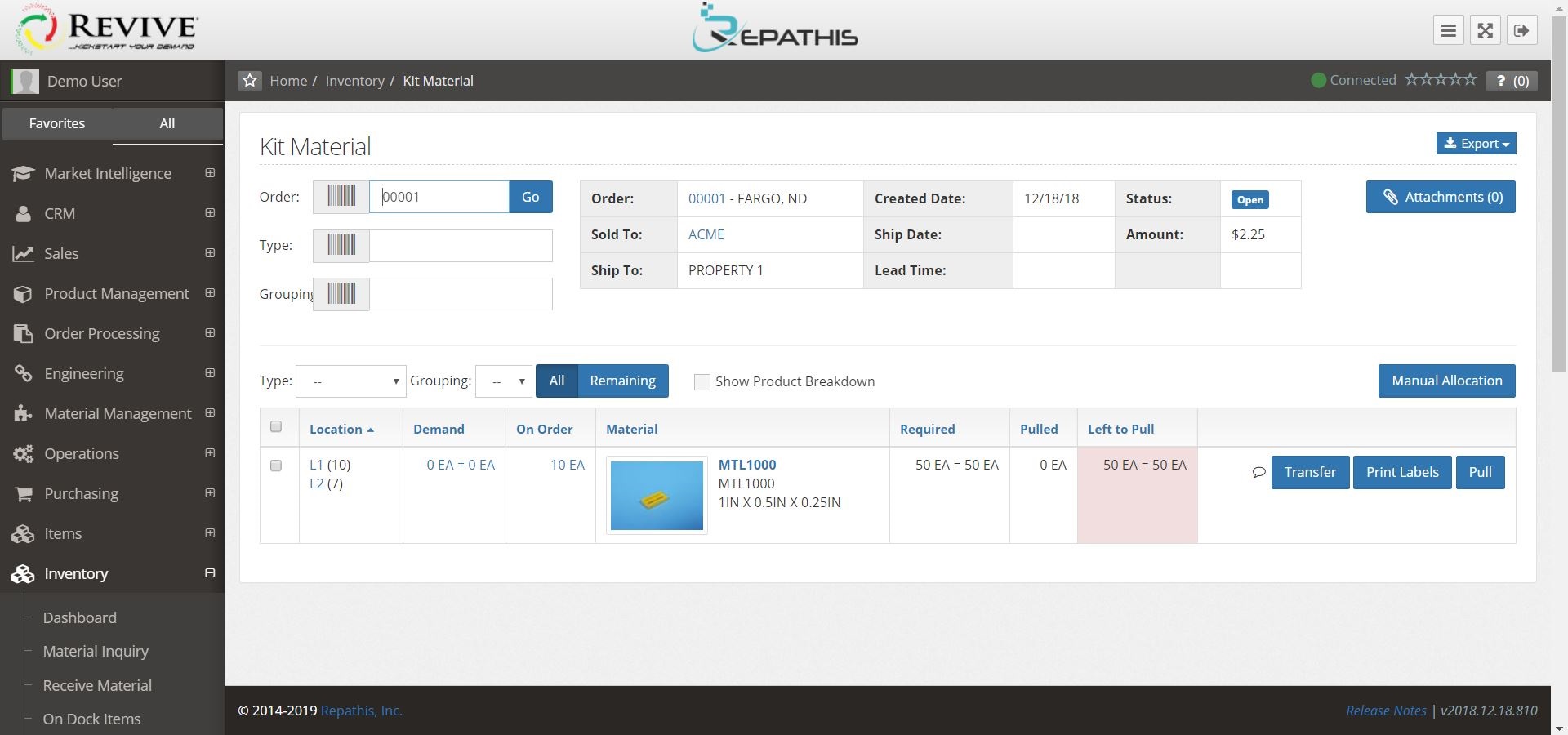

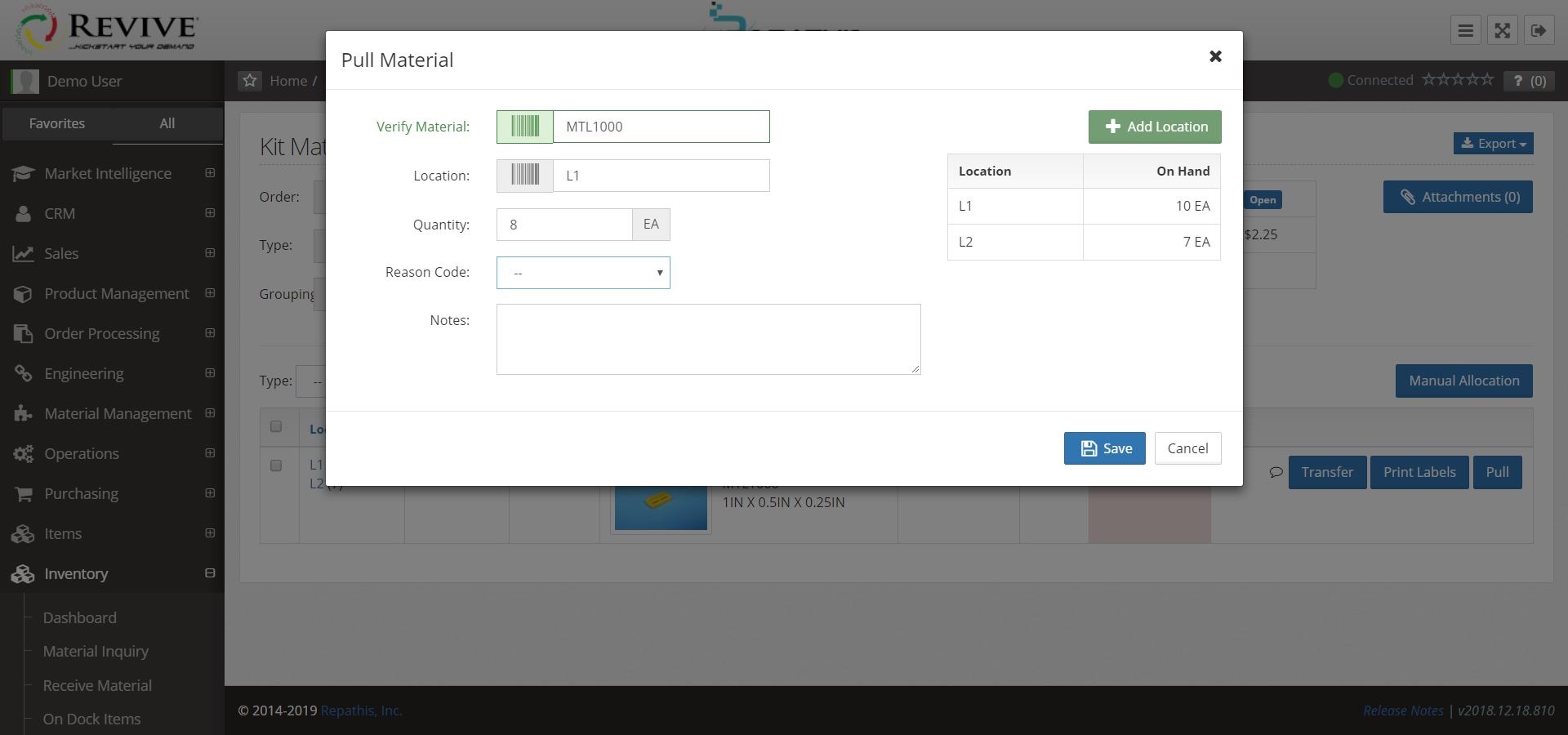

KITTING & RELEASING

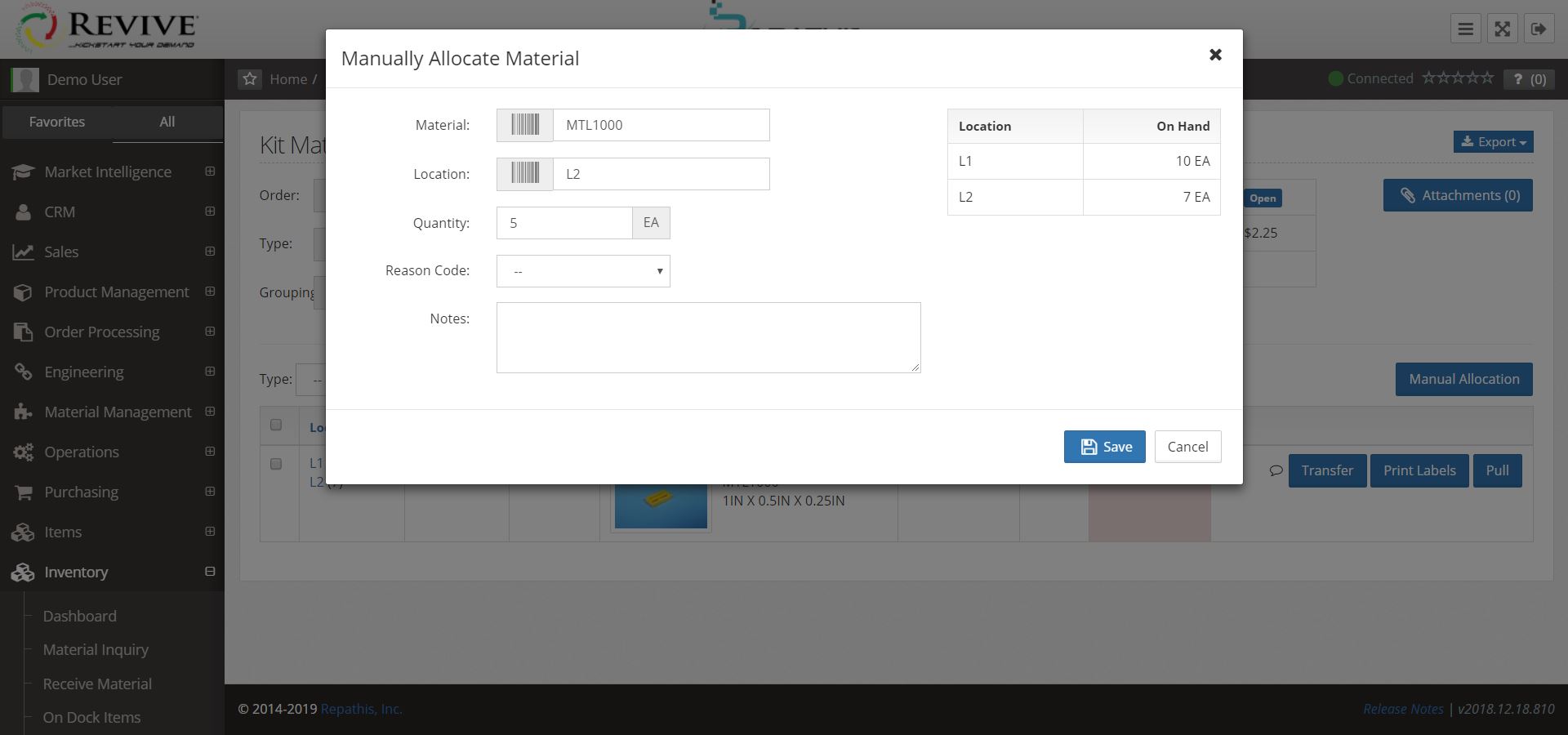

With our kitting & releasing features, every movement of material out of inventory is tracked and recorded. Order labels can be scanned to show material requirements, how much has been pulled, and how much is left to pull. Items can then be kitted to that specific order using our quick and simple scanning system. Items can also be released to the production floor or manually allocated. Already-pulled items can be released back to stock for corrections or released to another order for priority changes. This system works for your team, so that your team can work more efficiently.

- Kit items to a specific Order

- Release items to the Production Floor

- Manually allocate items

- Print labels

- Release back to stock

- Release to another Order for expediting/priority changes

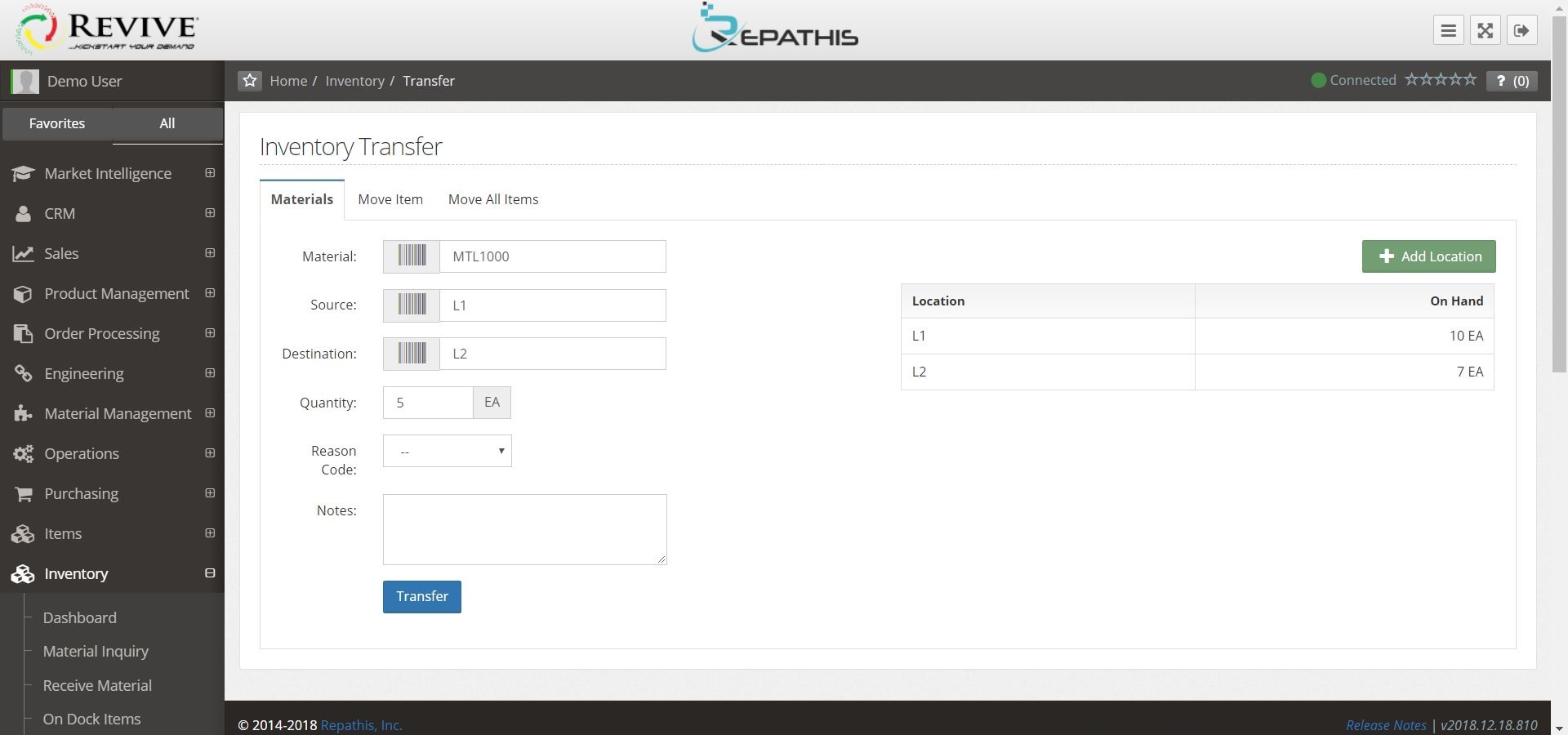

MISCELLANEOUS

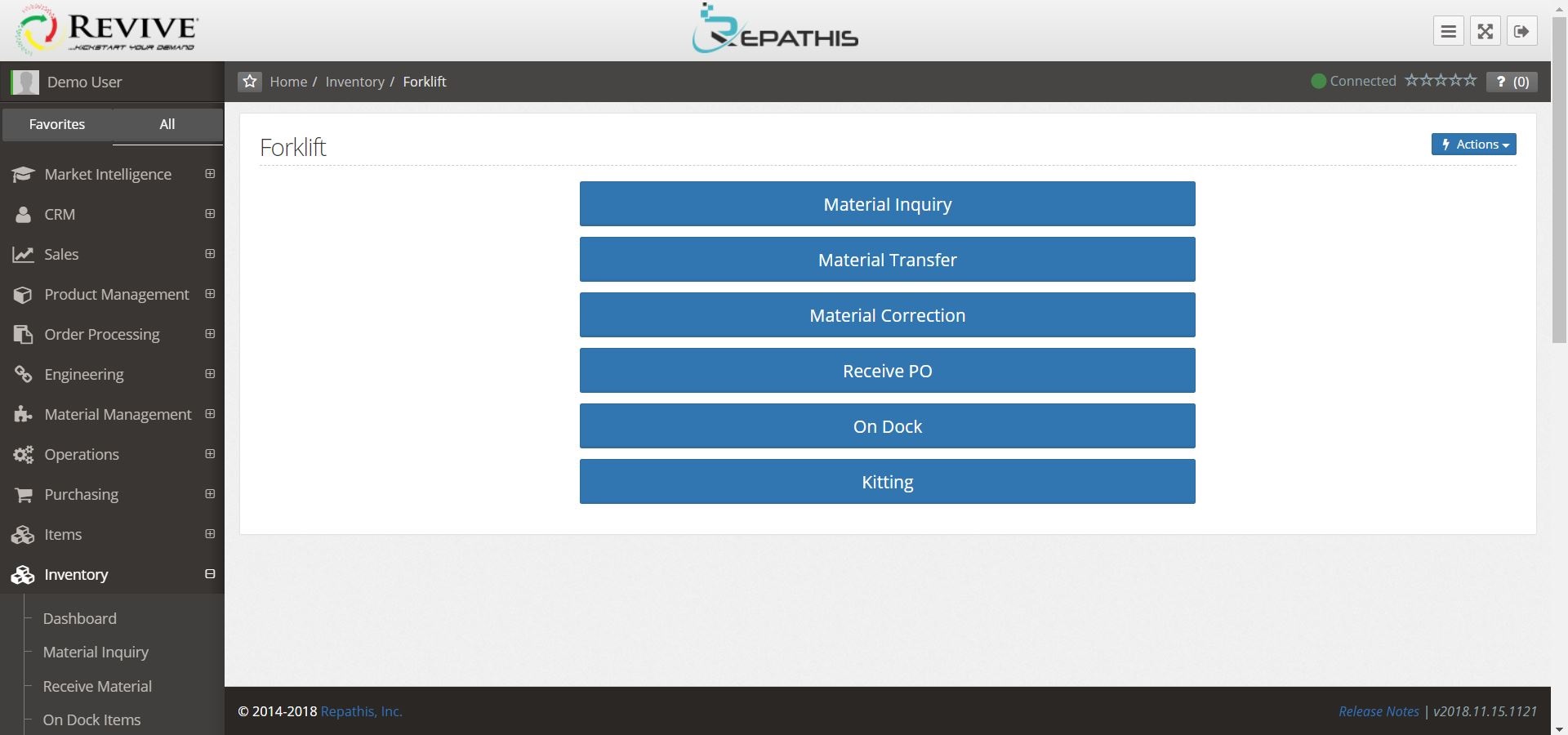

- Item Transfers

- Track Consignment Material

- Forklift Screen

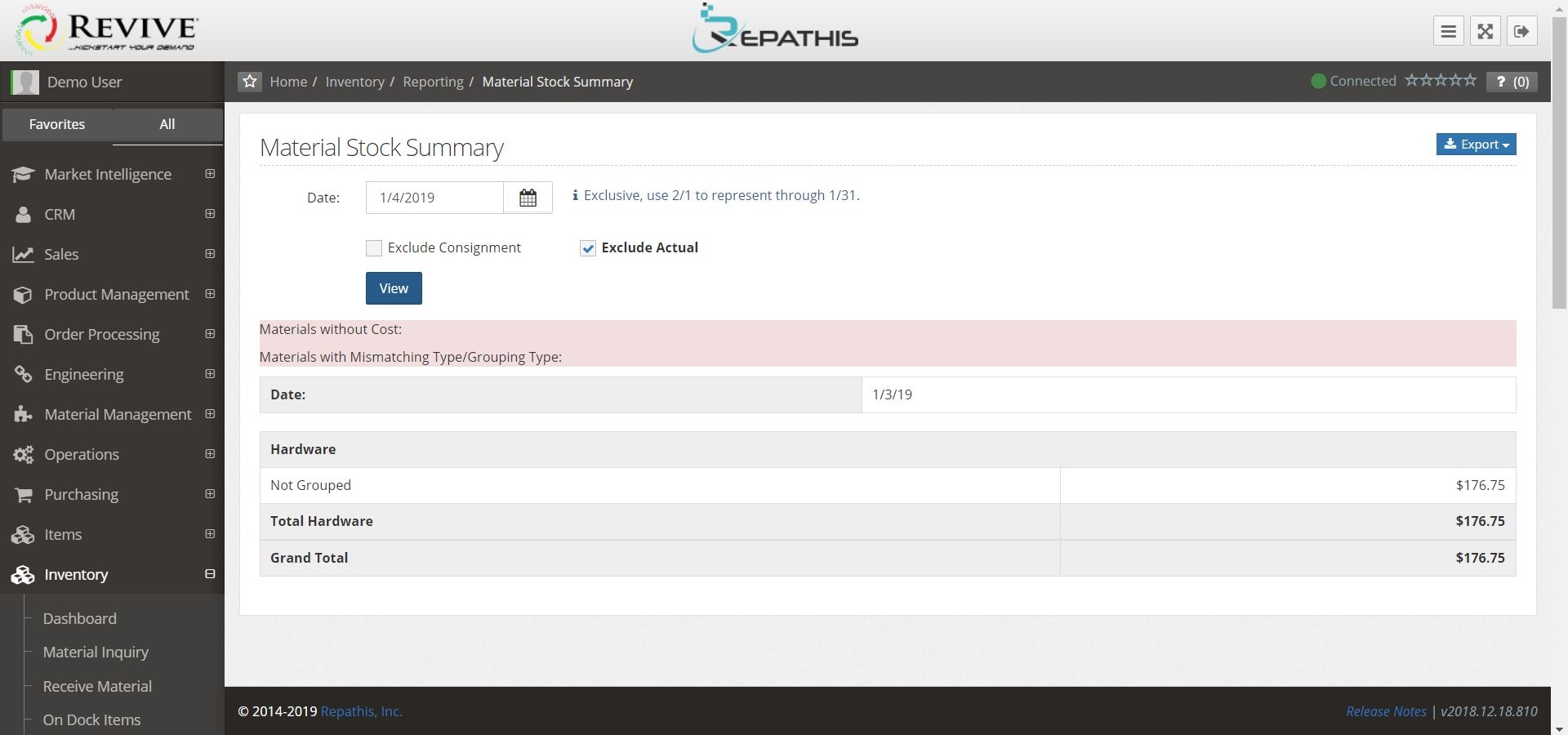

- Reporting