Why Revive's Quality Module?

When quality is at the heart of your business, you need a quality management system that meets and exceeds your high standards, so that you can exceed the standards of your customers. From testing and tracking to problem-solving and insights, Revive’s Quality Module supports your team with every aspect of quality management.

Efficiently record quality tests and collect important information with the audit feature. The comprehensive deviation feature not only allows you to keep record of all deviations, but aids you in identifying and correcting the source of the issue. Automatic communications and workflows are integrated throughout the module to ensure that relevant information is dispersed to every necessary team member or department, keeping your teams aligned and efficient. Data and reporting features provide important insights, allowing you to make informed, strategic decisions.

Customizable, comprehensive, and streamlined. It's time you implement a quality management system that provides the best to your business, so you can provide the best to your customers.

FEATURES

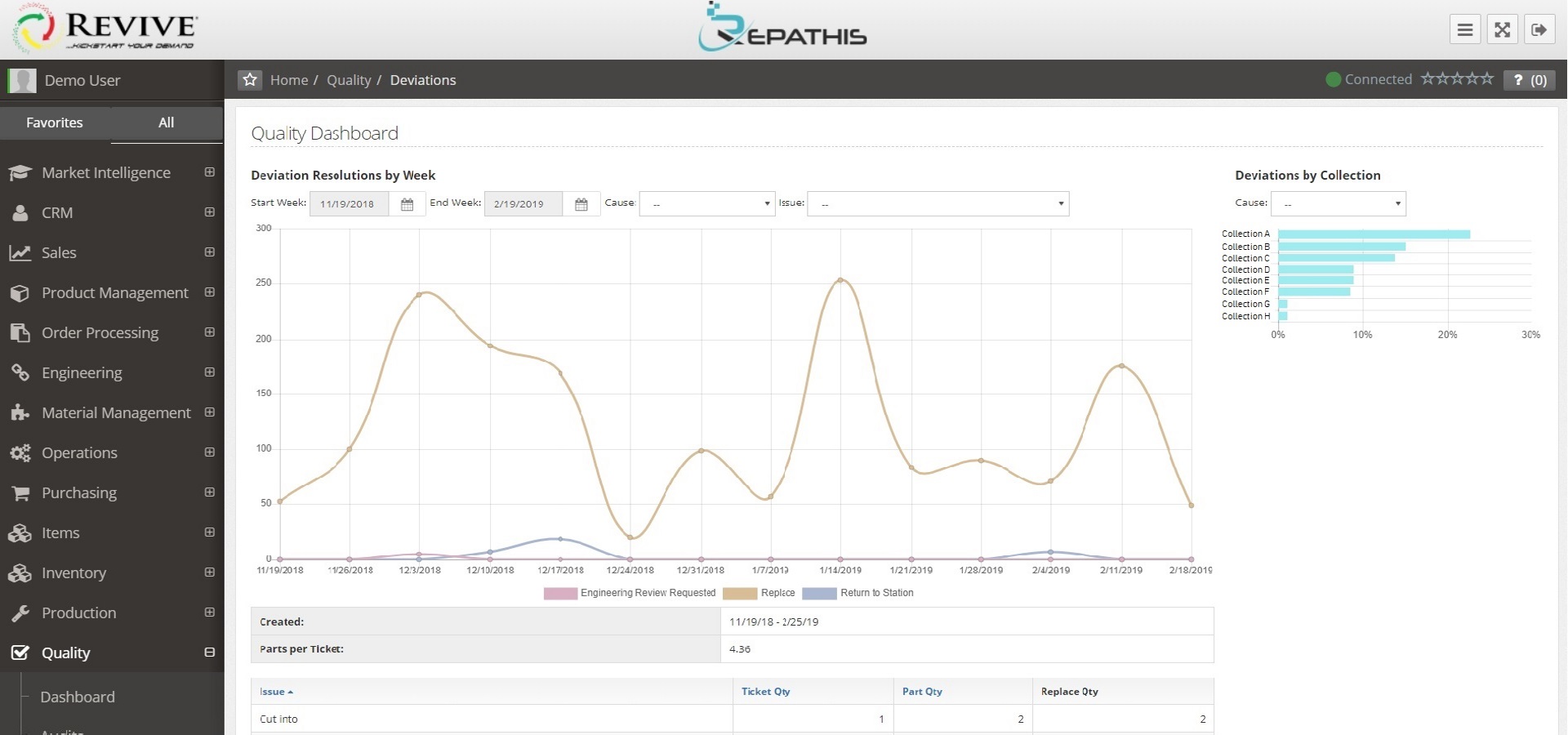

DASHBOARD

Access a quick, summarized view of your quality metrics on one page. The Deviation Resolutions graph provides insight into your overall quality performance over time. Filter by cause and issue to gain a deeper view into deviation origins and outcomes. The Deviations by Collection graph allows you to understand which collections are experiencing the most deviations, and where those deviations are stemming from, so you can focus your problem-solving where it’s needed most.

- Track quality deviations over time

- Break down deviations by collection, cause, and issue

- View part deviation quantities and replacement part quantities for each issue

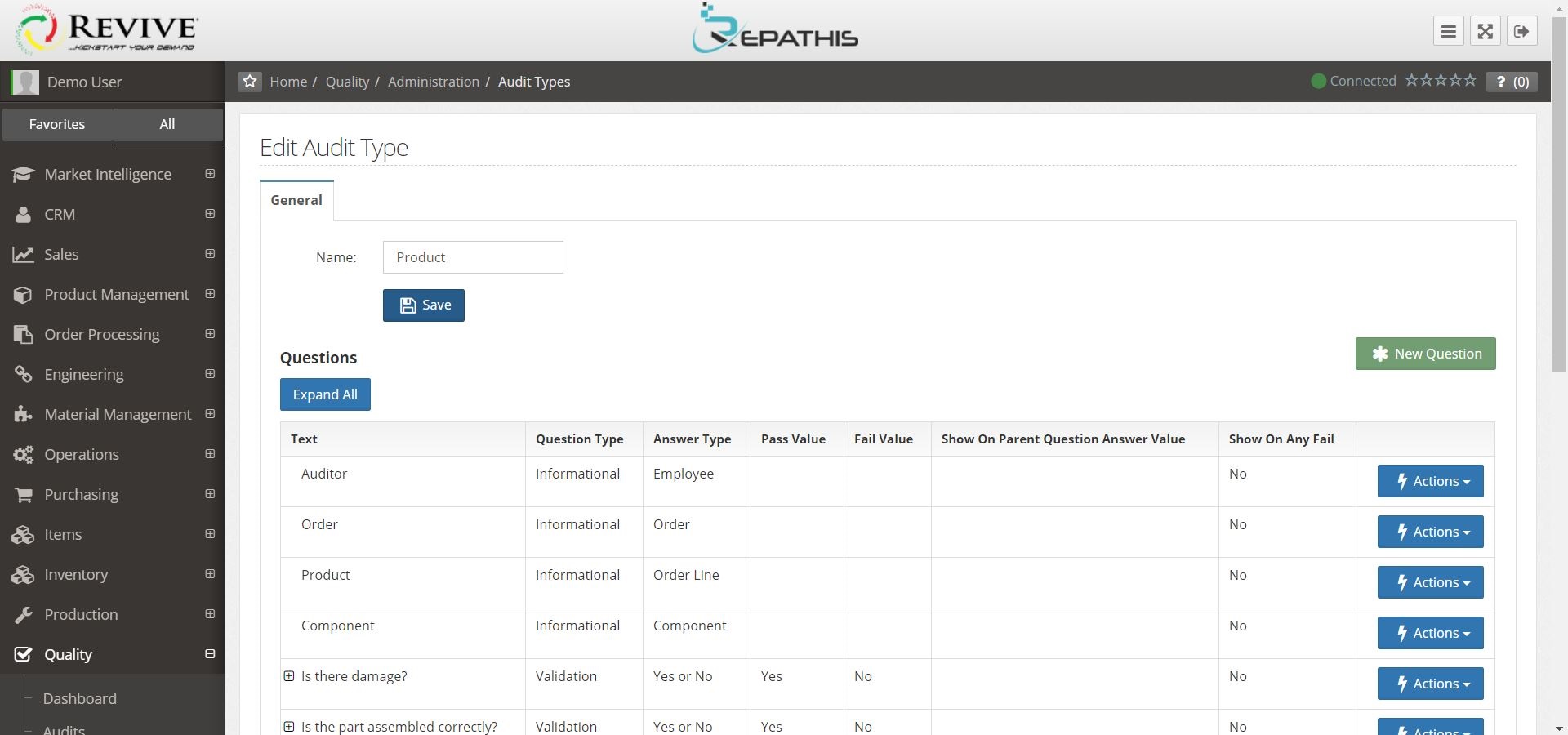

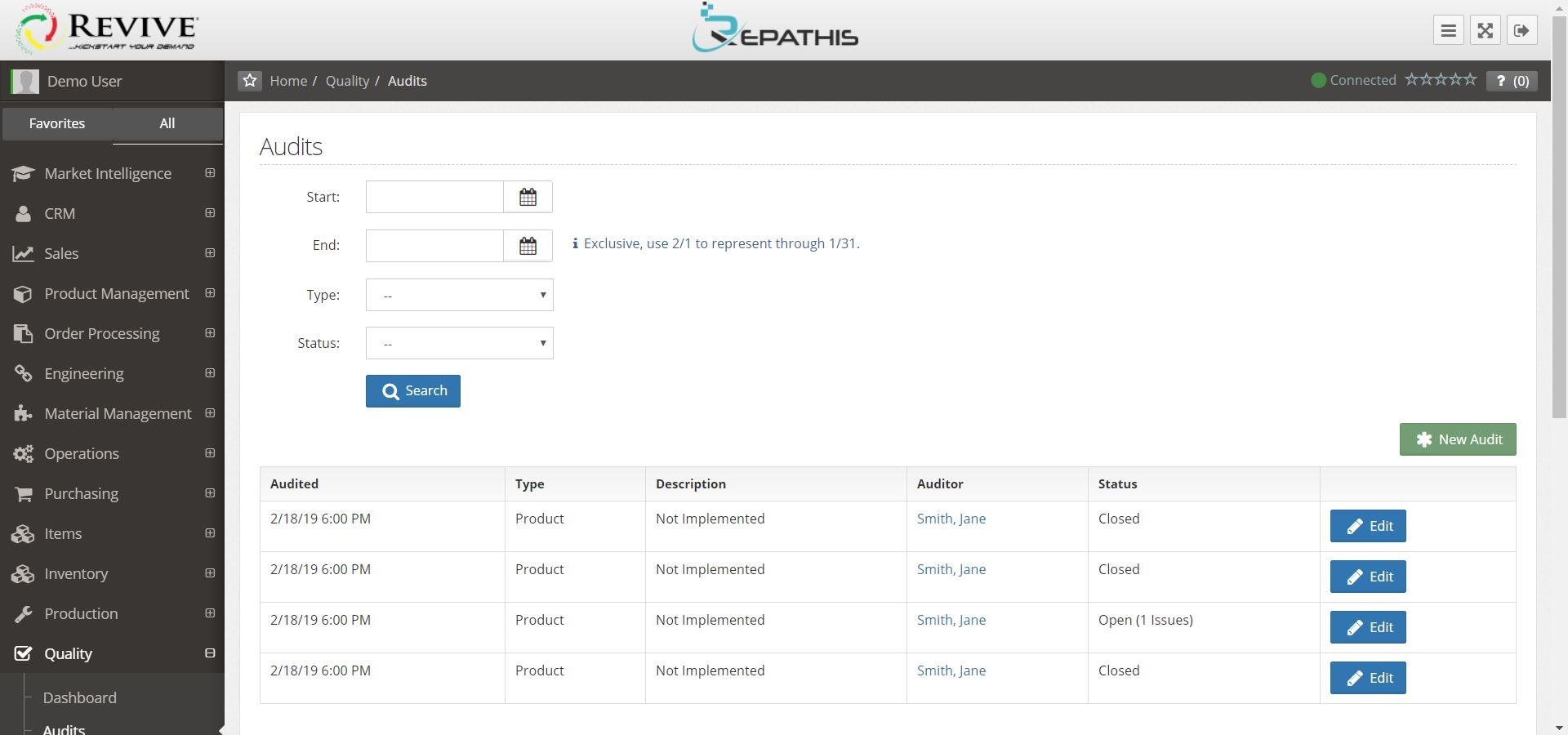

AUDITS

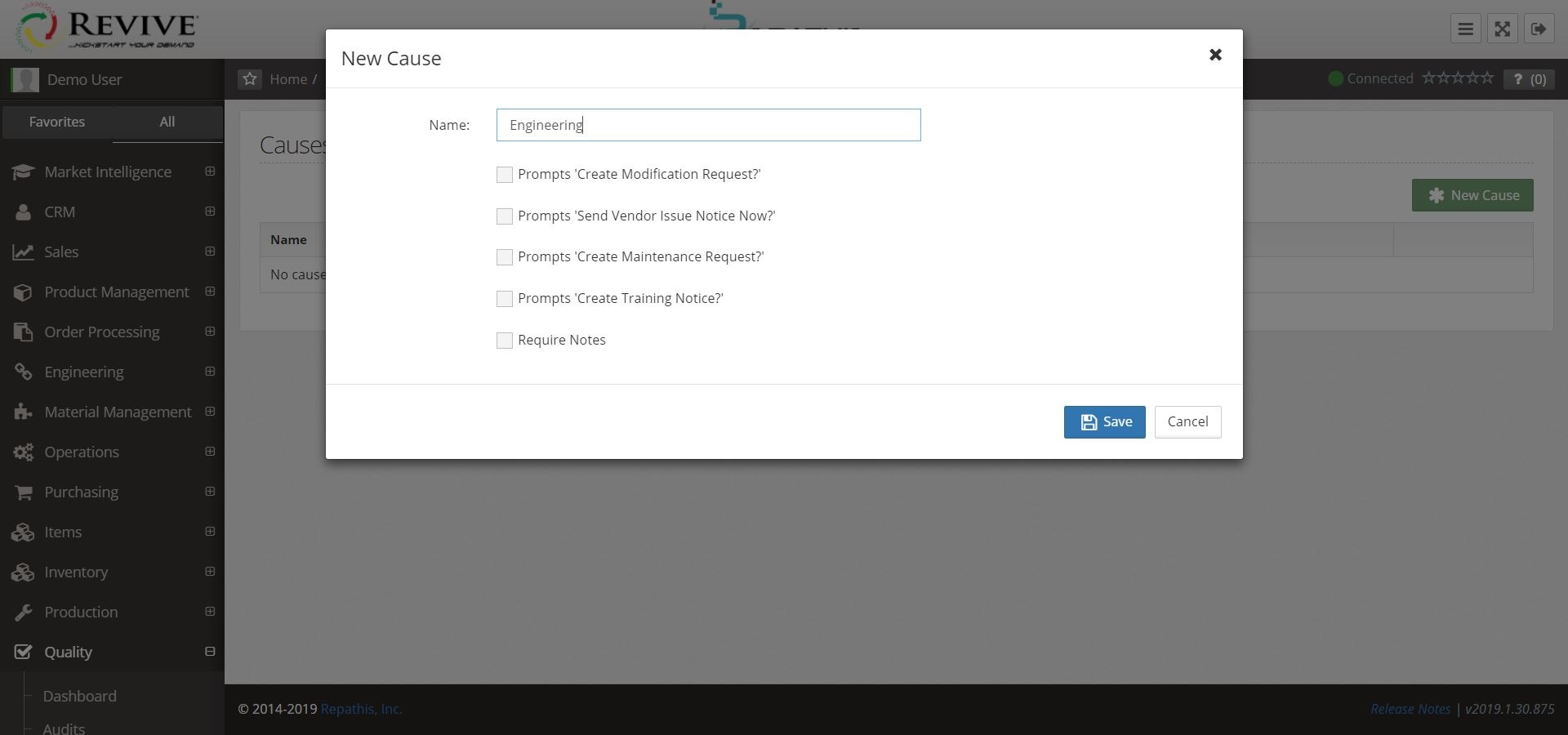

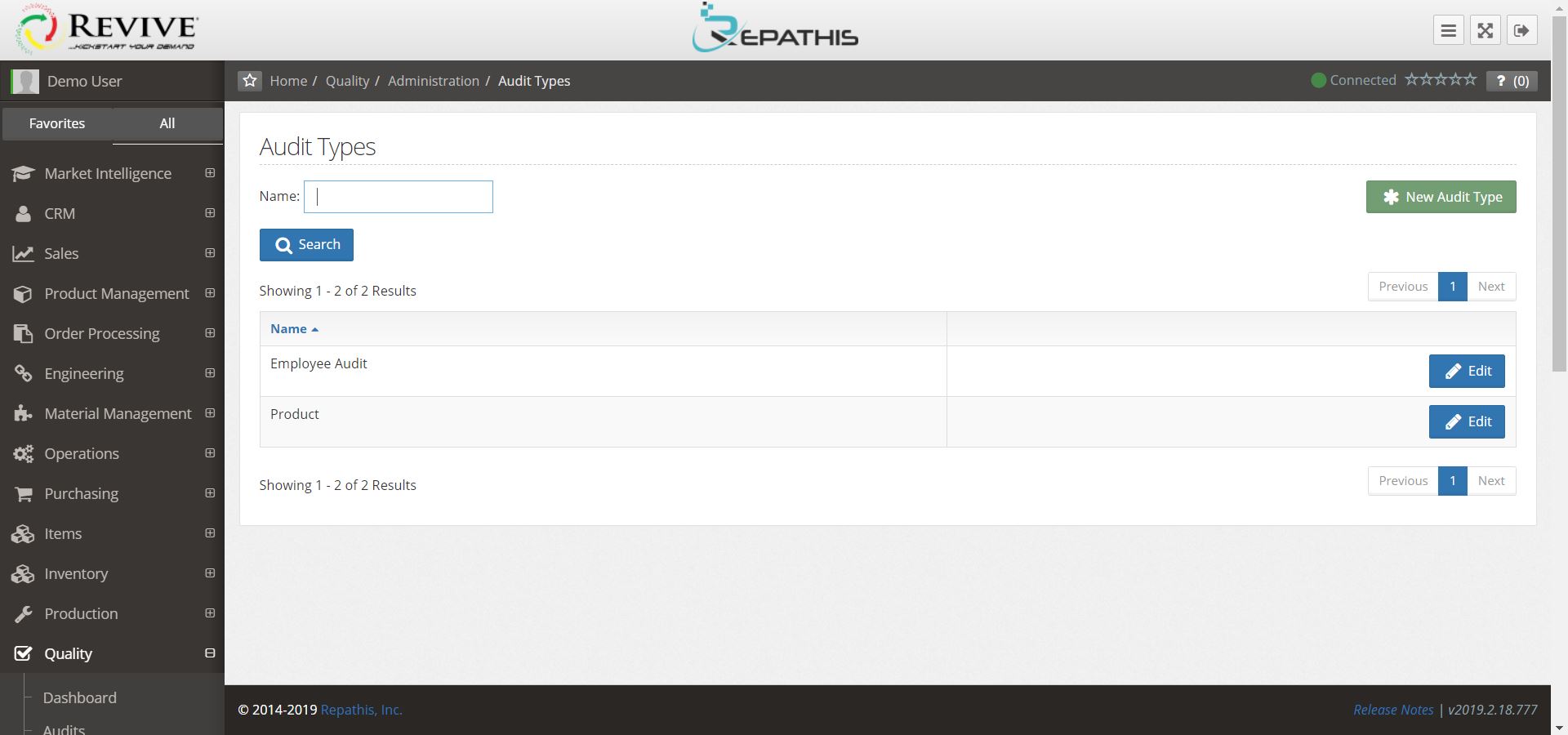

All product audits are recorded in the Audits feature. Auditors log necessary information and complete a quality questionnaire for each audit. Different audit types can be configured for different needs; questions are completely customizable. “Negative” questionnaire responses indicating a deviation cause the report to be marked as “Unresolved,” prompting the necessary team members to view the report and resolve it as necessary. “Negative” questionnaire responses can also prompt additional questions or note boxes so that sufficient information can be gathered about the potential deviation. Record structures and questionnaires can be customized to fit your business, so that you can efficiently test and improve quality measures that are important to you.

- Keep record of all product audits

- Audit questionnaire standardizes data collection

- Customize audit formats for different audit types

- Audits are marked “Unresolved” when “negative” responses are given

- Audits are closed when “negative” responses are resolved

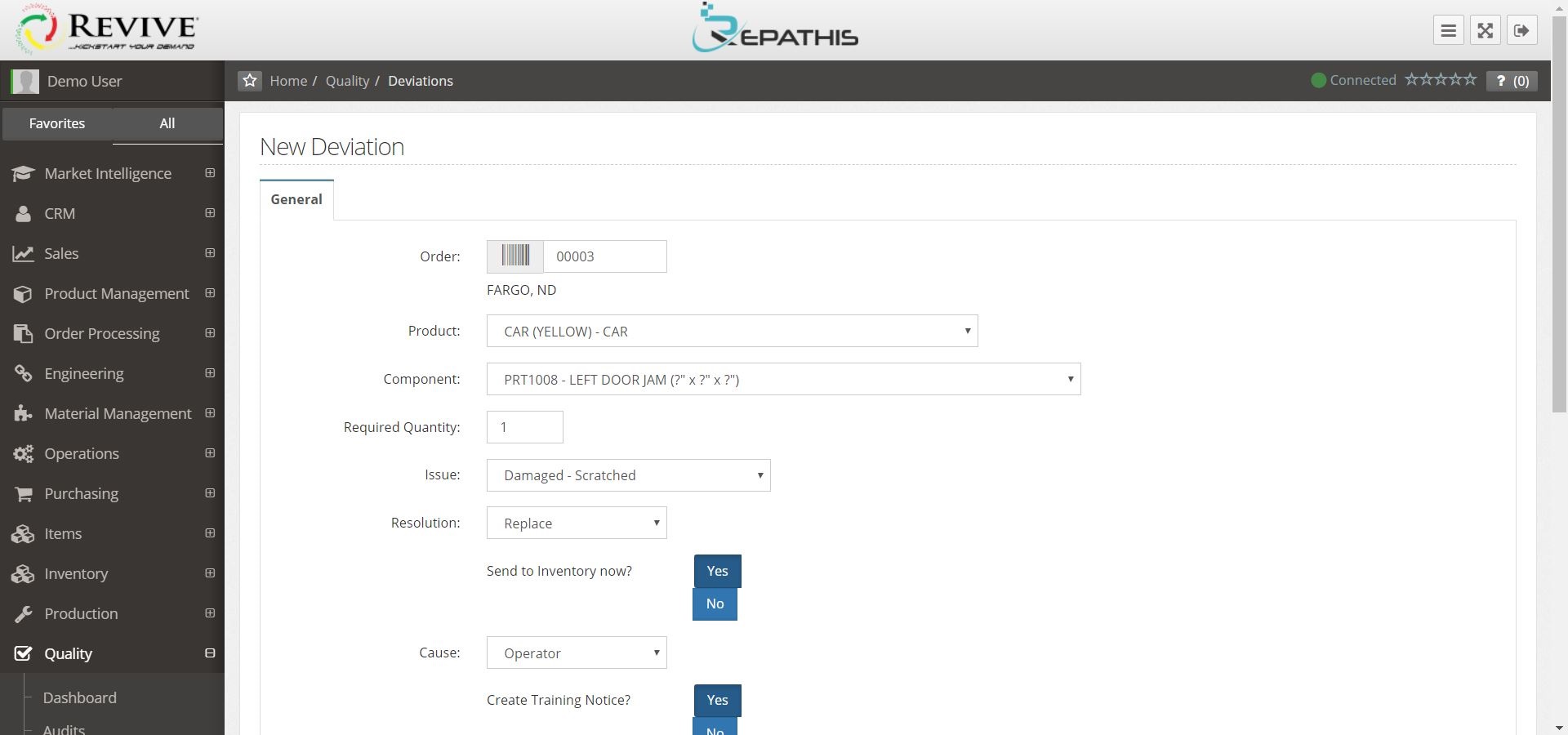

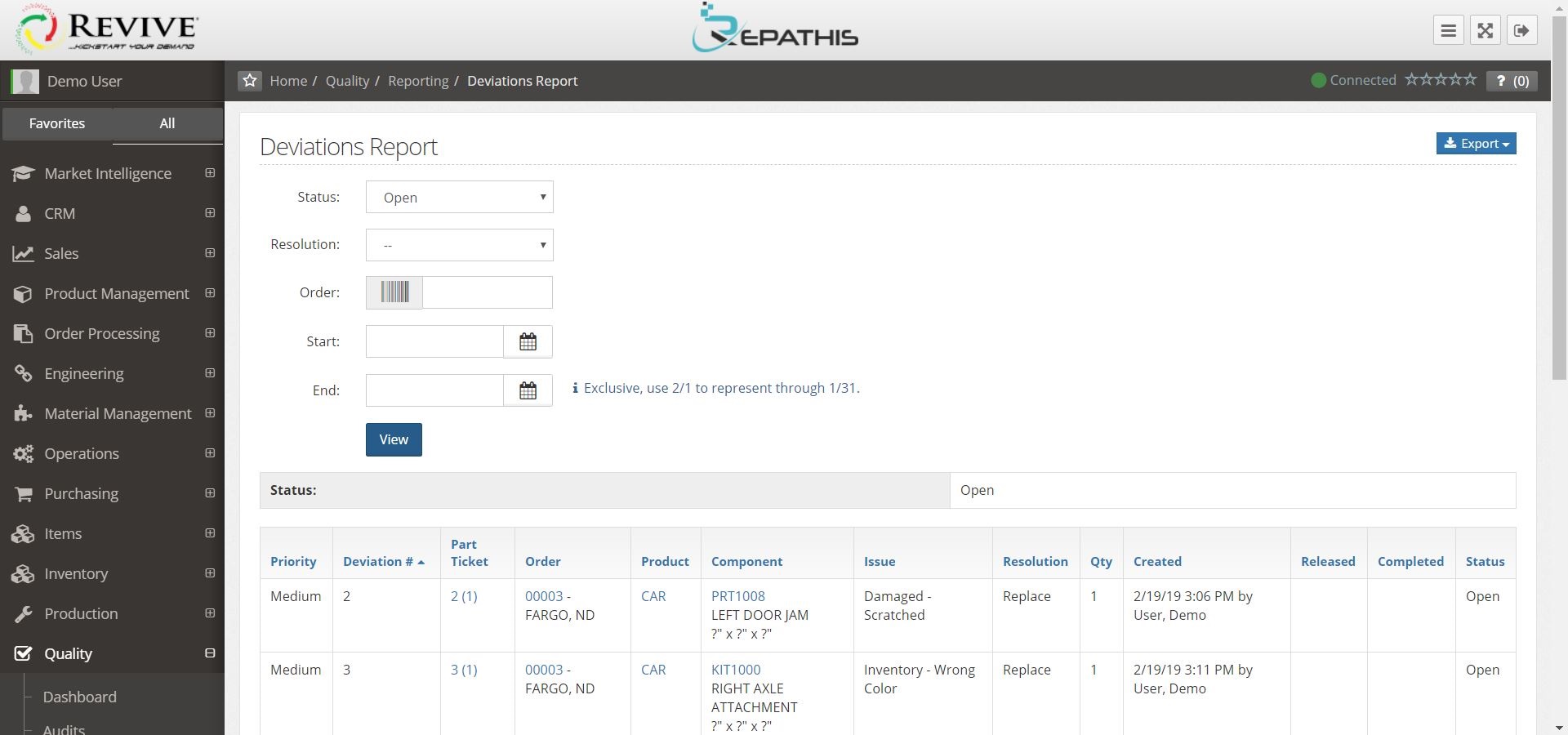

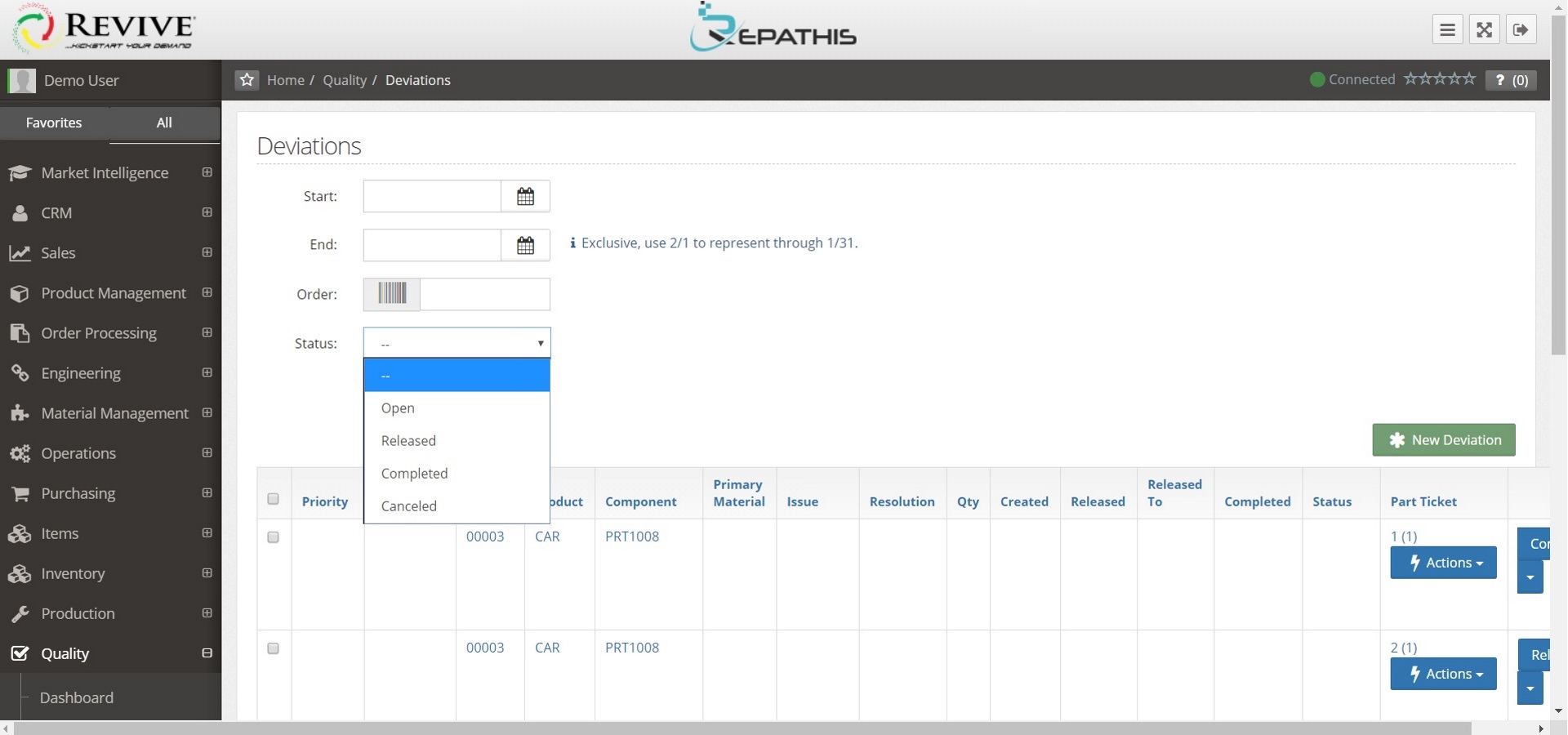

DEVIATIONS

The Deviations feature allows you to keep track of and easily search all deviation records, while making communication between departments quick and simple. Once a deviation has been identified, team members can easily create a record with information on the deviation and its resolution. Each resolution can trigger appropriate communications and/or workflows to the necessary departments to ensure accurate and timely information is dispersed. Once a deviation record is created, it will automatically create a part ticket with information regarding the deviation to be easily printed and attached to the product and sent to its routing destination. A deviation record will remain open until an assigned manager reviews it and releases it to production, and will close once production is completed.

- Deviation records are simple to create and track

- Selected deviation resolutions and causes can trigger communications and/or workflows to necessary departments

- Deviation records automatically create part tickets with matching information to send with the product to its routing destination

- Deviation records remain open until product is released to production by assigned managers and production is completed

MISCELLANEOUS

- Reporting

- Admin