Why Revive's Planning Module?

In today’s market, success no longer relies simply on having great data; it relies on gaining critical insights from that data. You need a tool that will tell you what and when to purchase and what and when to manufacture, so that you can operate efficiently and competitively. The information and insights provided by Revive’s Planning Module will make it your team’s most valuable tool.

Easily plan production and assess capacity with Revive’s Master Production Schedule. Let the Planned Order Schedule alert you of the best amounts and times to order and produce based on net requirements. Dig deeper into scheduling details for individual items by opening the Time Phased Record for each item in the Planned Order Schedule.

Revive’s Planning Module handles the tedious analysis of your data to provide you with useful information your team needs to operate at their best. Take the guesswork and inefficiency out of your planning, and take a big step forward with Revive.

FEATURES

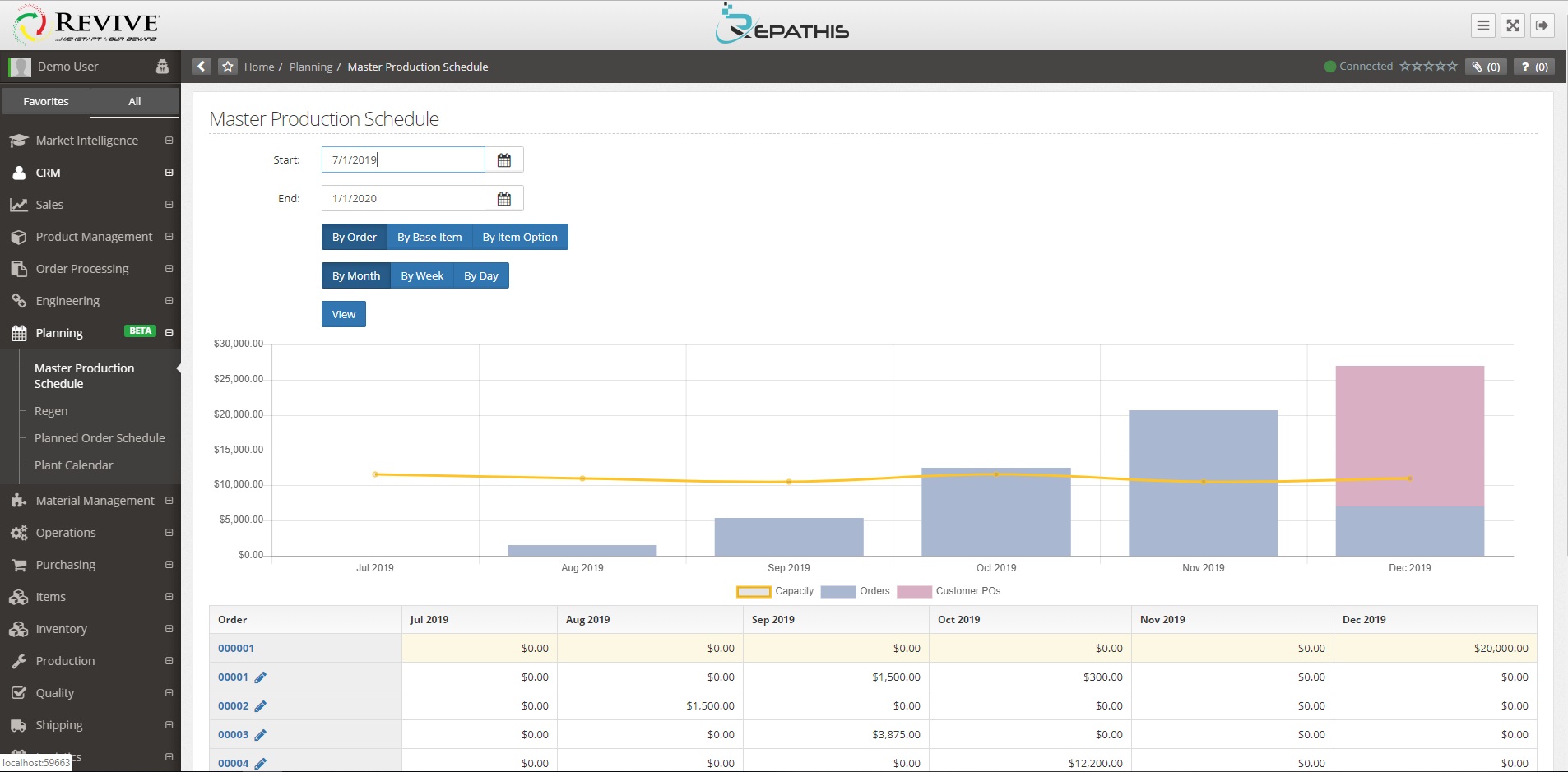

MASTER PRODUCTION SCHEDULE

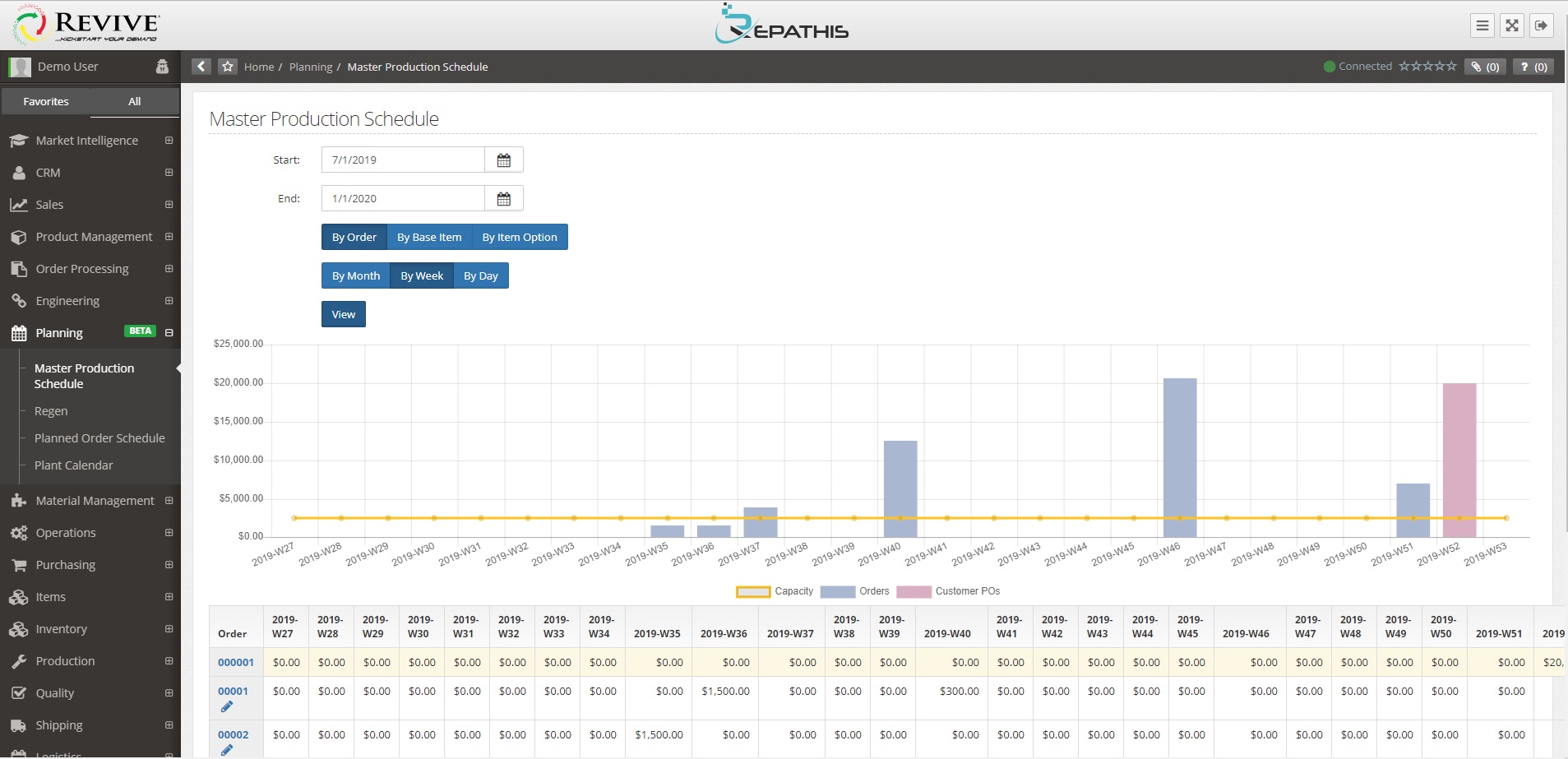

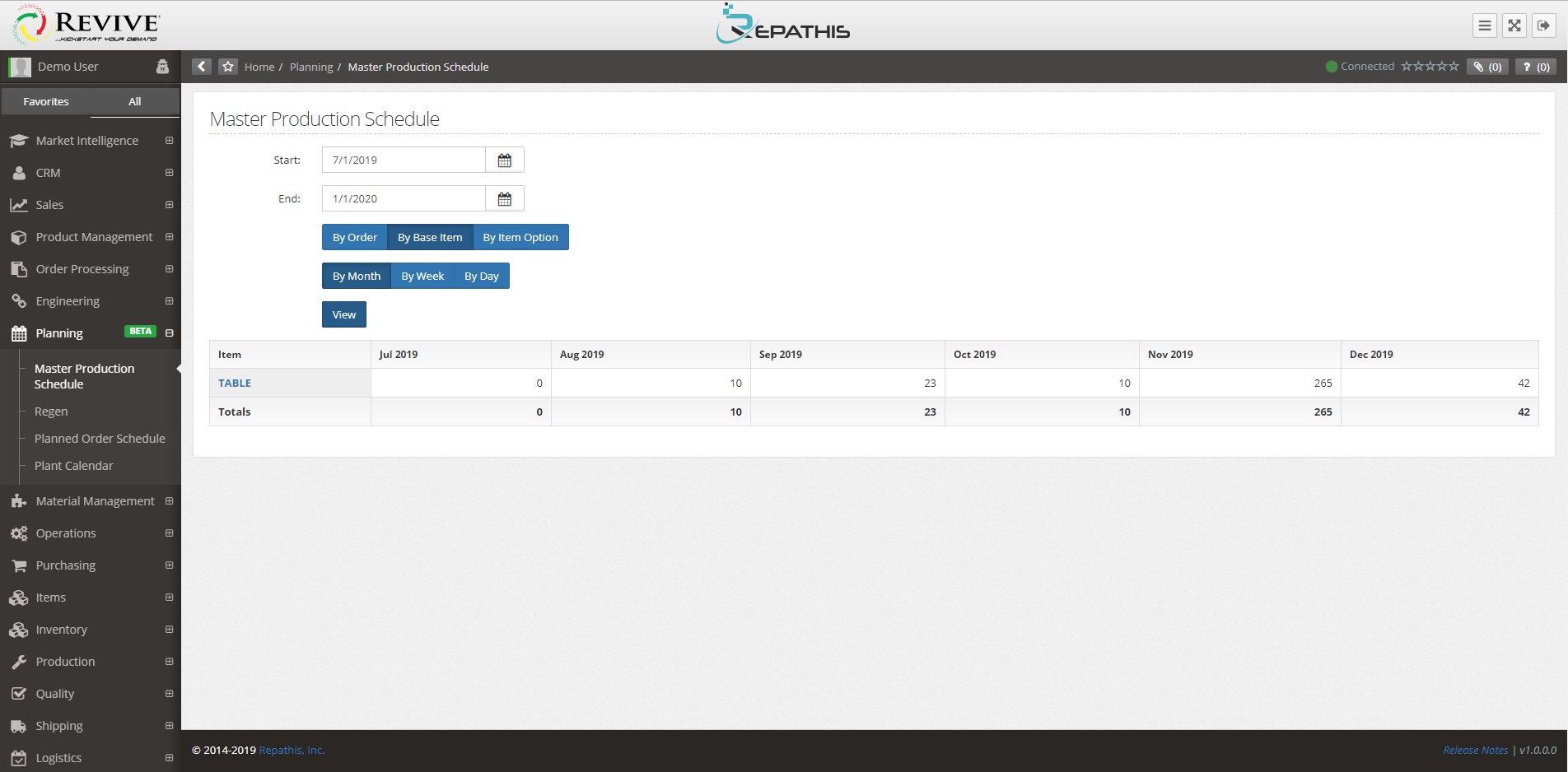

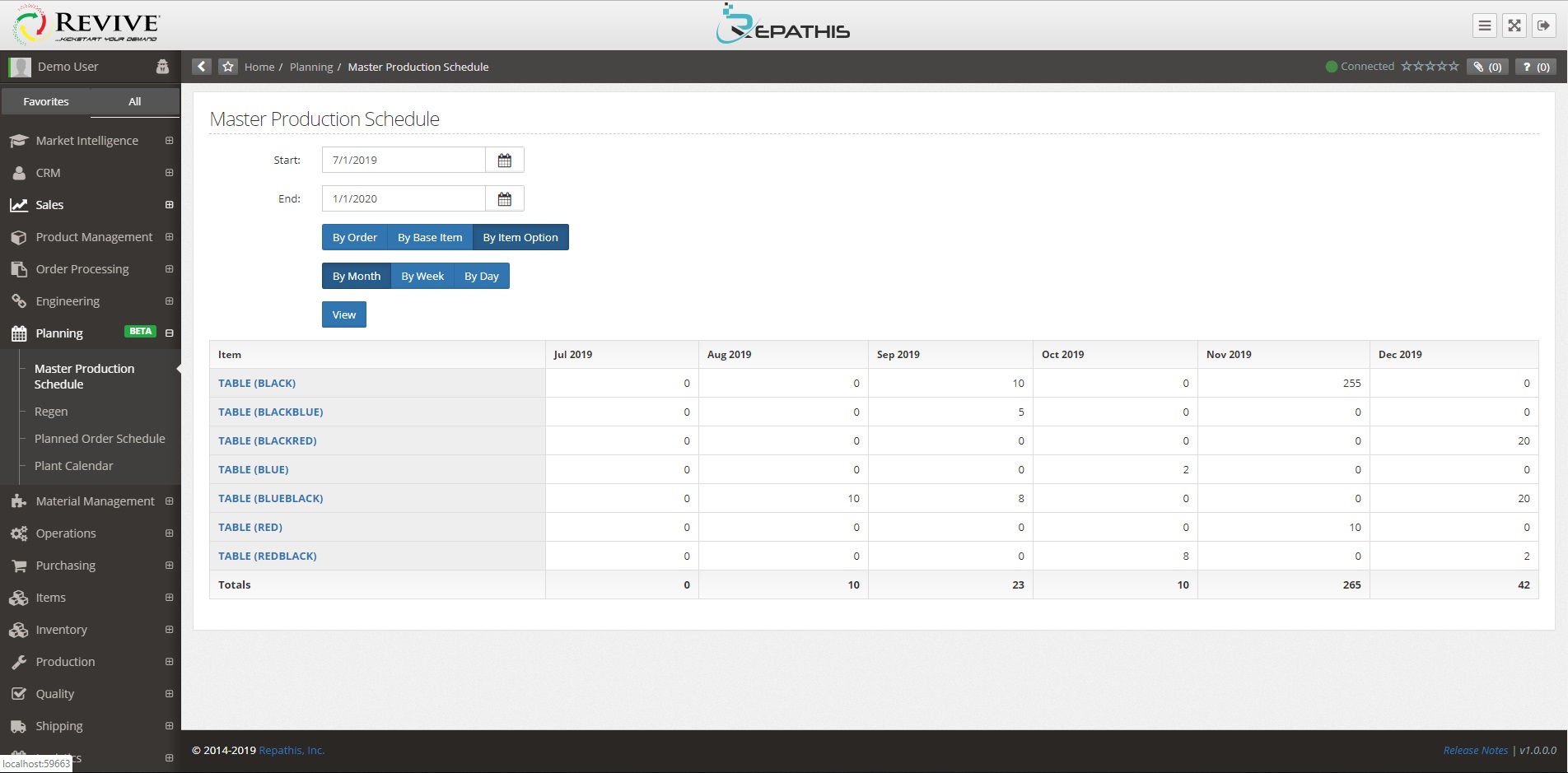

Enjoy a complete view of your production schedule with the Master Production Schedule feature. View your demand as Order Dollar Amounts, Base Item Quantities, and Item Option Quantities and filter your view by month, week or day. View your capacity relative to demand to determine whether your team will be operating above, at, or below capacity. You can also enter dates from this page for when order items and components are to be produced.

- View demand as Order Dollar Amounts, Base Item Quantities, and Item Option Quantities

- View by month, week, or day

- View capacity relative to demand

- Enter production dates for order items and components

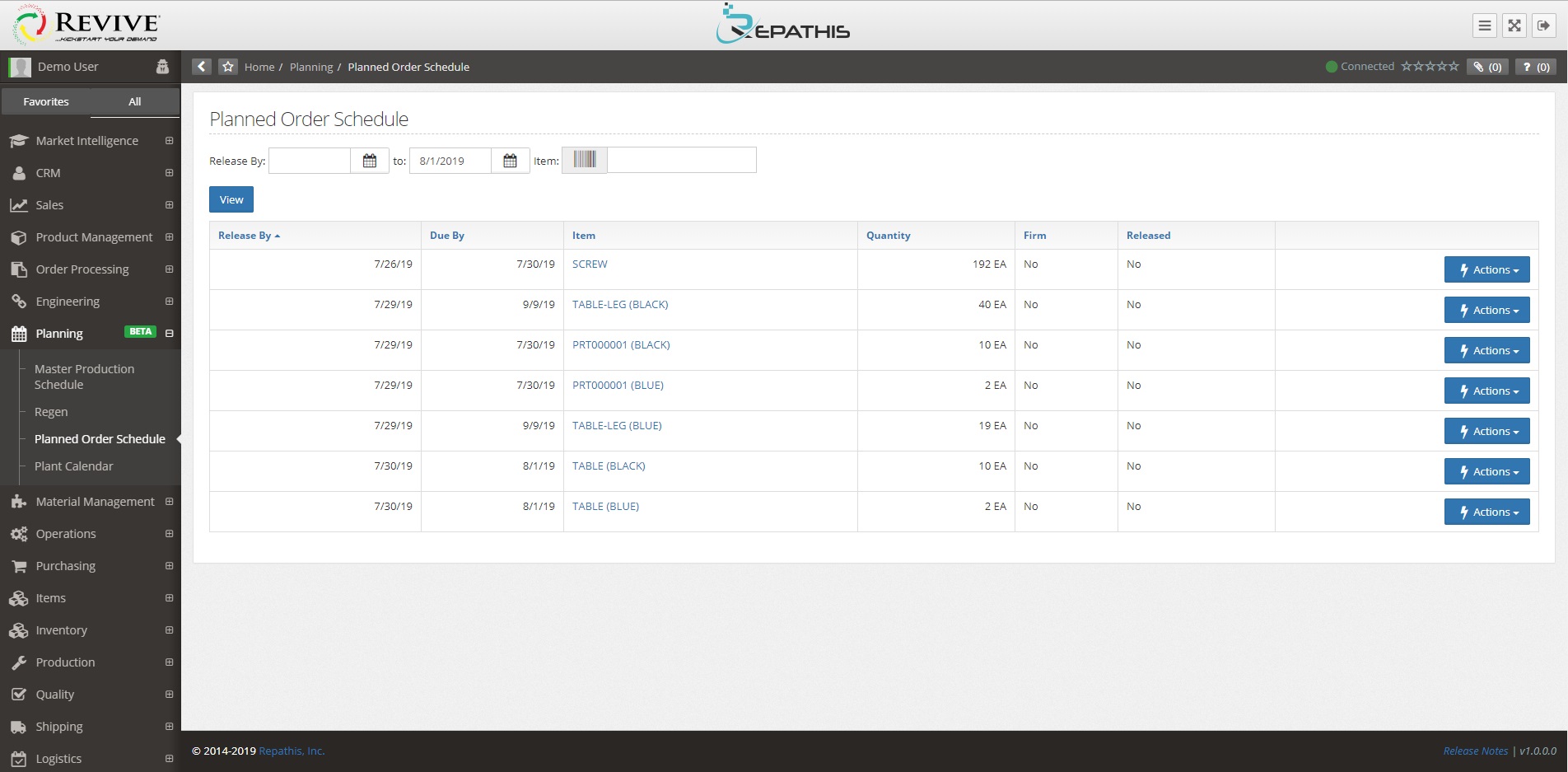

PLANNED ORDER SCHEDULE

In the Planned Order Schedule feature, you can view Revive’s suggested order and purchasing schedule for your team based on demand, supply, and inventory data. This schedule includes release date, due date, item, and quantity. If an order is marked “Firm,” it remains fixed, meaning the system will plan and regenerate around those orders without changing them. This schedule communicates with other modules as well. Release to Purchasing creates a purchase requisition in the Purchasing Module, so the purchasing manager can issue a PO to fill the requisition. Release to Manufacturing creates a manufacturing order (part ticket/work order) in the Production Module.

- View the suggested order schedule based on net requirements

- View Release Date, Due Date, Item and Quantity

- Set “Firm” orders which remain fixed in the schedule

- Create purchase requisitions and manufacturing orders in the Purchasing and Manufacturing Modules directly from the Planned Order Schedule

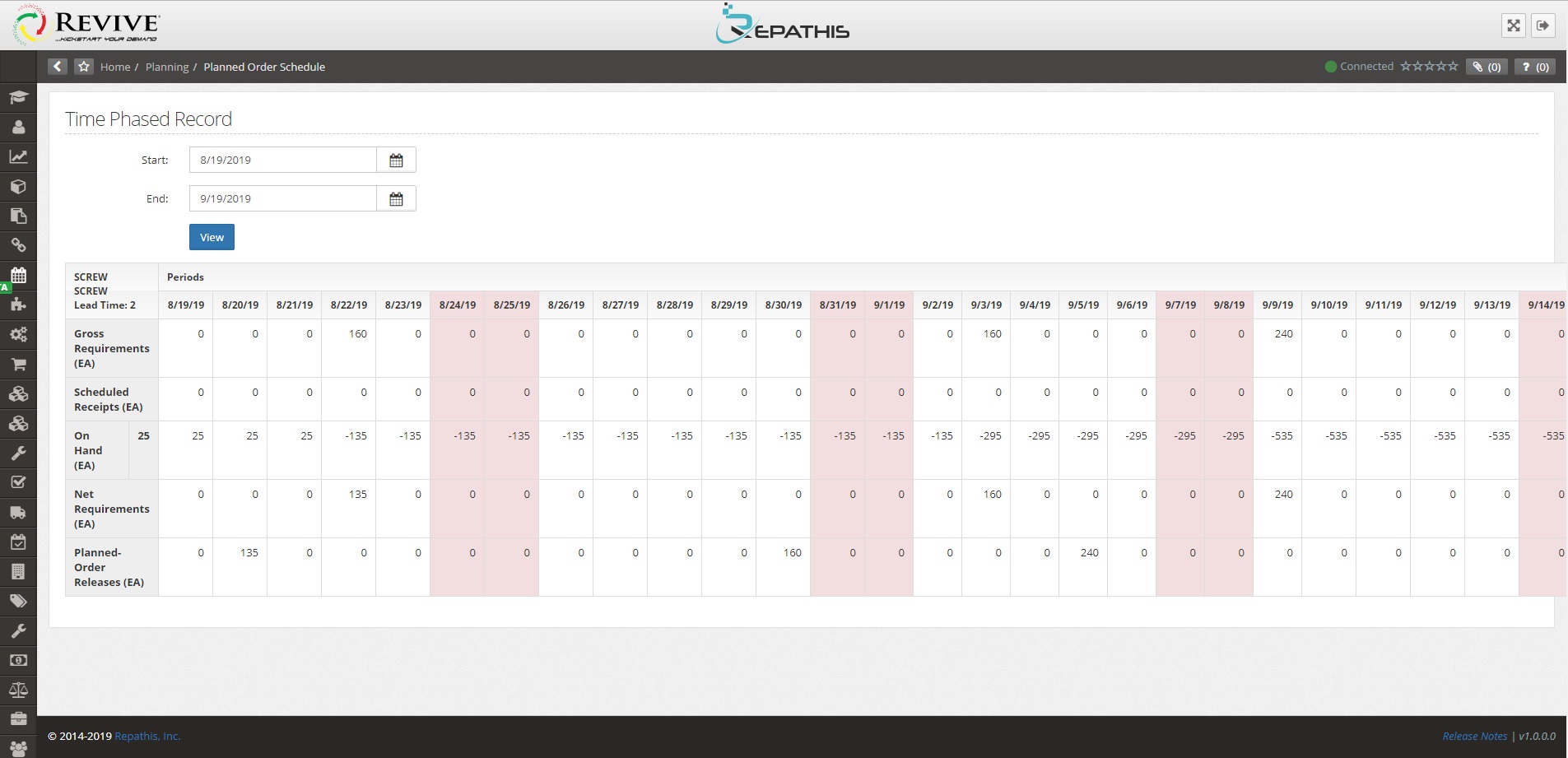

TIME-PHASED RECORD ANALYSIS

The Time-Phased Record Analysis feature allows you to see all planning details regarding a particular item, including demand, supply, inventory, net requirements, and planned order releases. This in-depth information facilitates your planning decision-making so that you can make the best item purchasing, manufacturing, and usage judgments.

- See all detail regarding a particular item, including:

- Demand – Gross Requirements

- Supply – Scheduled Receipts

- Inventory – On Hand and Projected

- Net Requirements

- Planned Order Releases

- Facilitate planning decisions with in-depth information on requirements, receipts, and inventory status

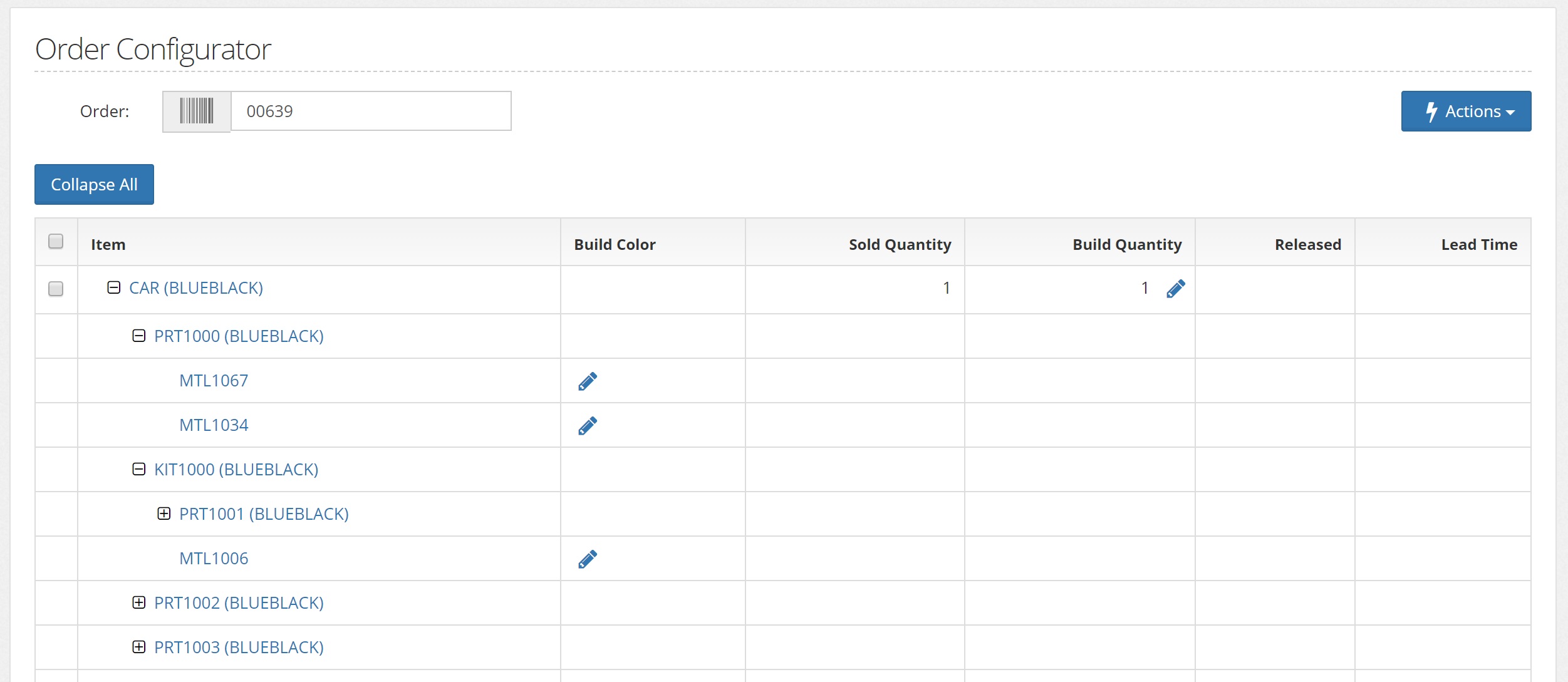

ENGINEERING - ORDER CONFIGURATOR

With the Order Configurator feature of Orders to Review in the Engineering Module, you can edit line item details for orders before they are released to the Planning Module. Configure colors for all parts of the BOM as needed and adjust build quantity. Once all changes have been made, easily release the order to the Planning Module directly from the Order Configurator.

- Configure color options for single line items

- Adjust build quantity

- Release configured orders to the Planning Module