Why Revive's Traceability Module?

When It comes to tracking your finished goods and orders, you and your team should never be in the dark. Revive’s Traceability Module not only ensures that you have complete, real-time data about your finished goods and orders, but it makes tracking and recording that data easier than ever.

The partially-automated tag generator allows you to save time when creating product and order tags while retaining enough control to ensure accuracy. Set up tag scanning stations to make tracking and recording information simple and quick at every point in finished goods’ and orders’ journey.

Traceability is imperative to your customer and partner relationships and business operations. Let Revive make your business’ traceability processes easy, efficient and accurate.

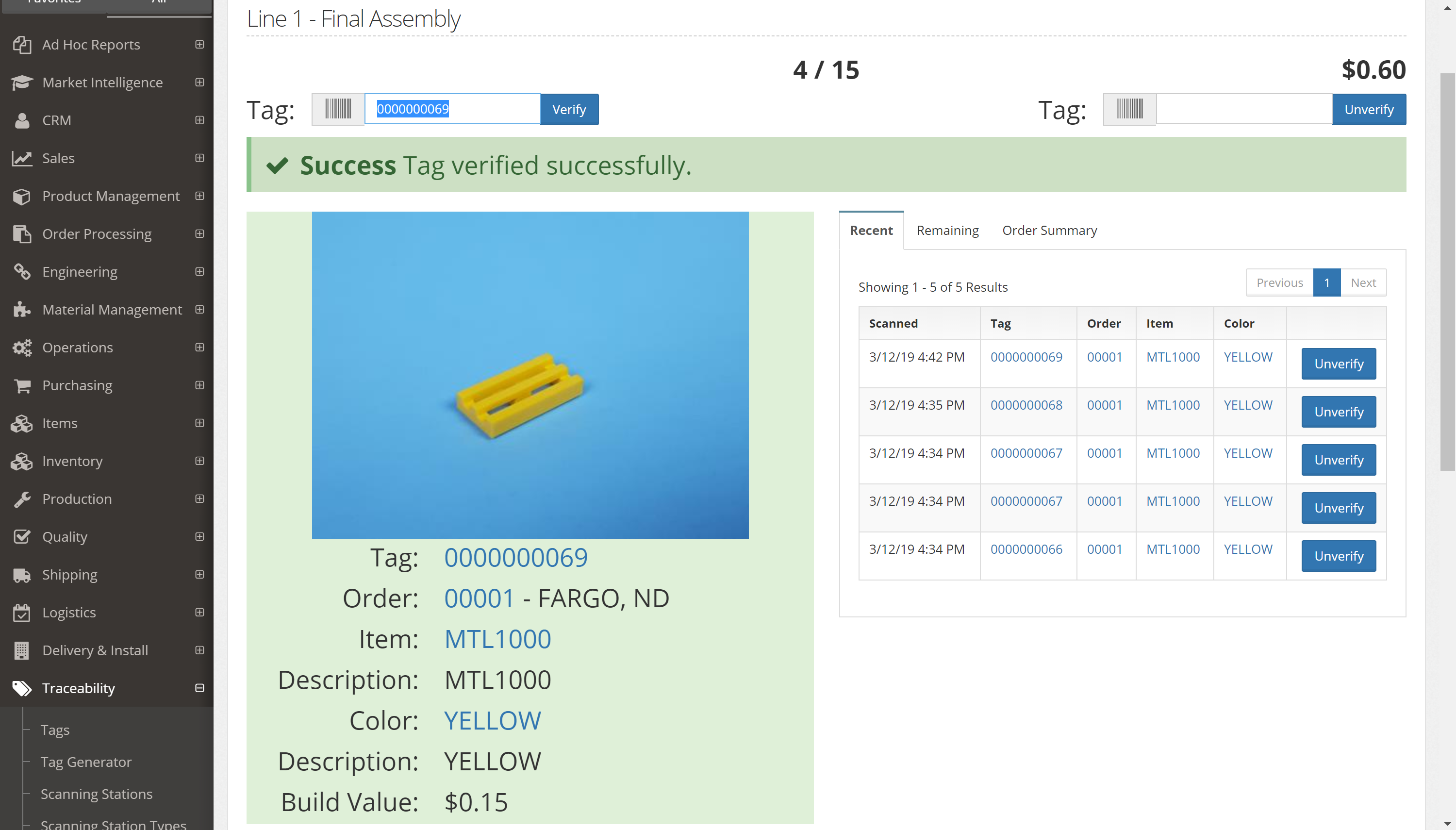

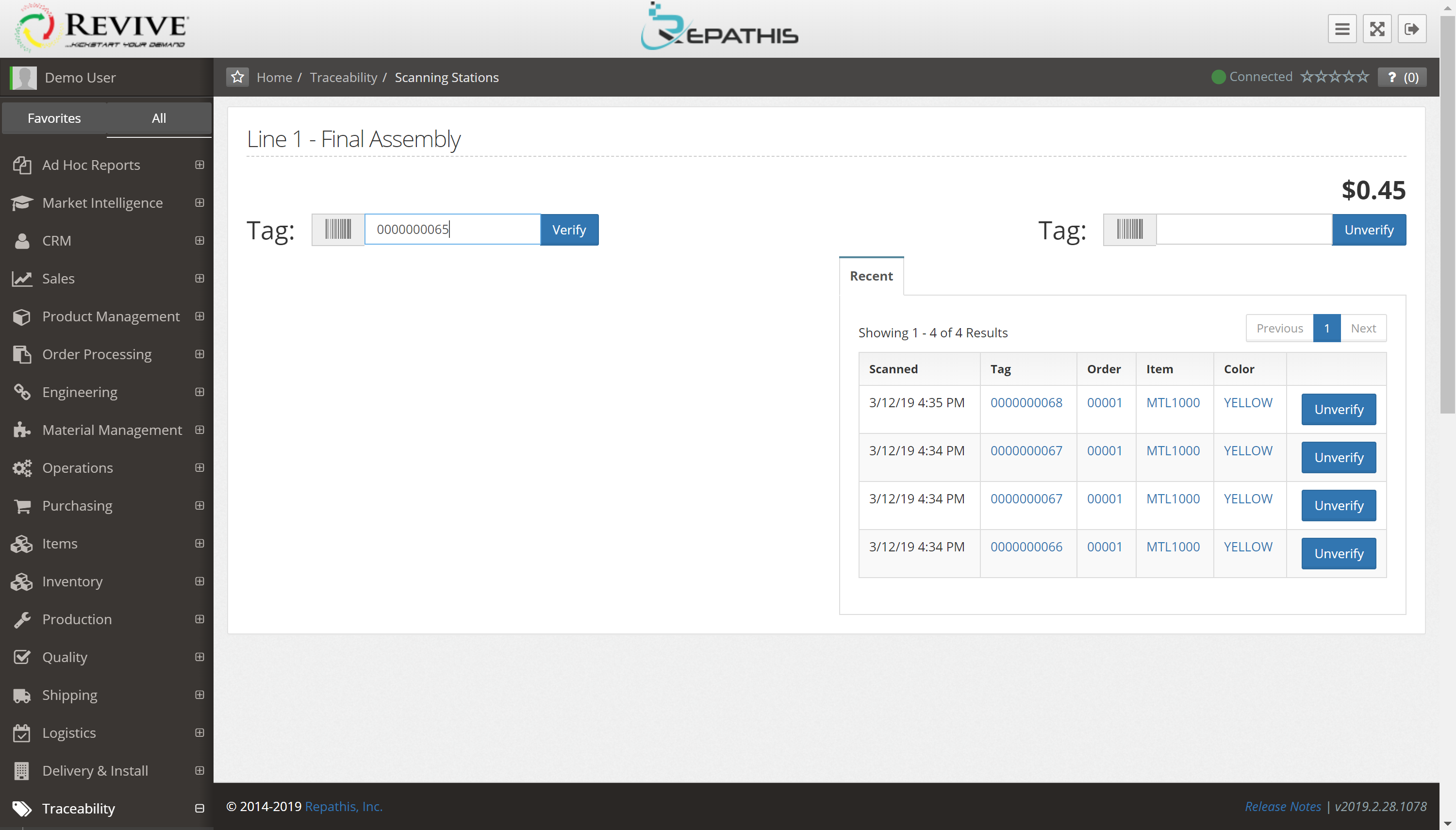

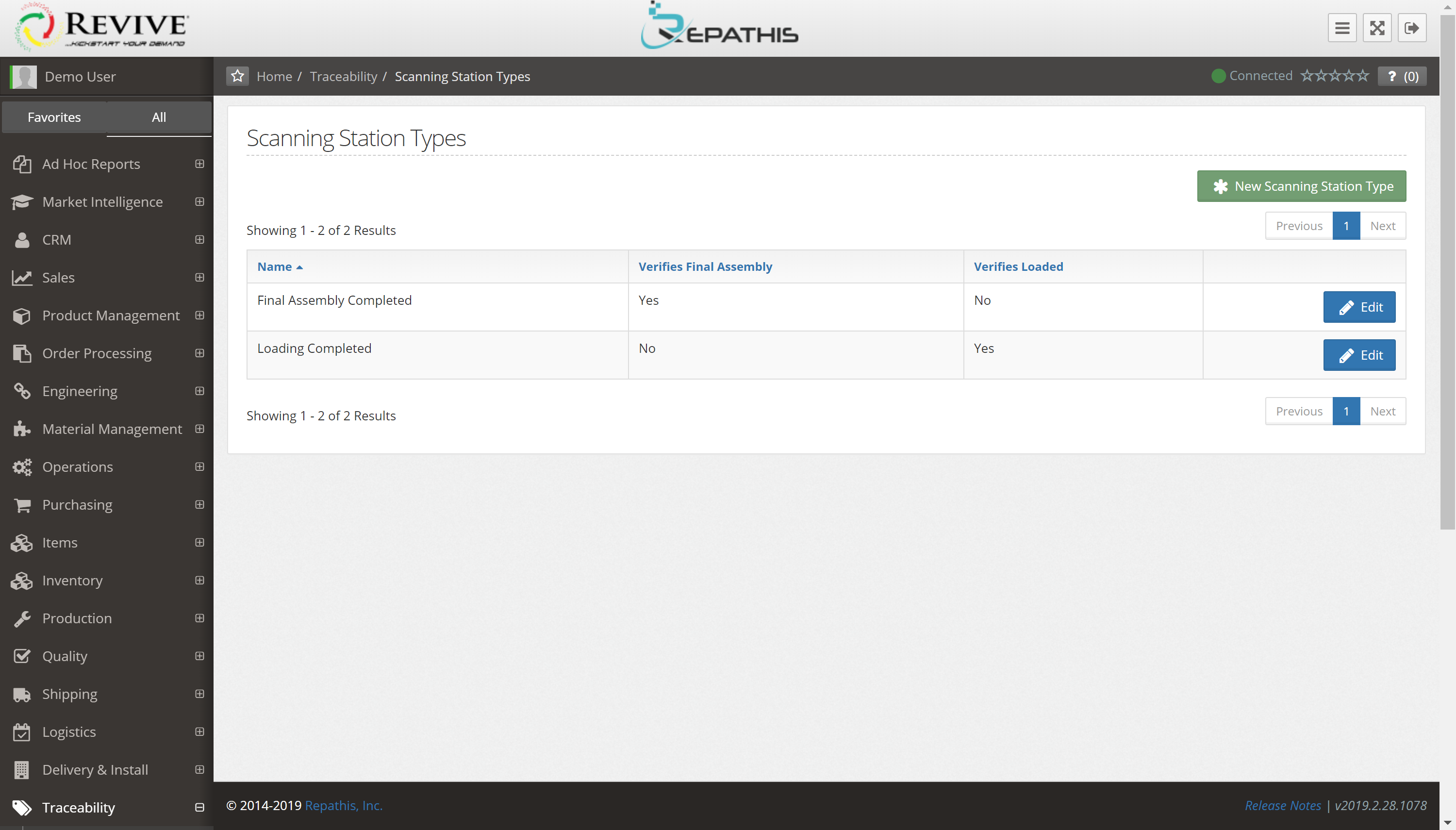

SCANNING STATIONS & TYPES

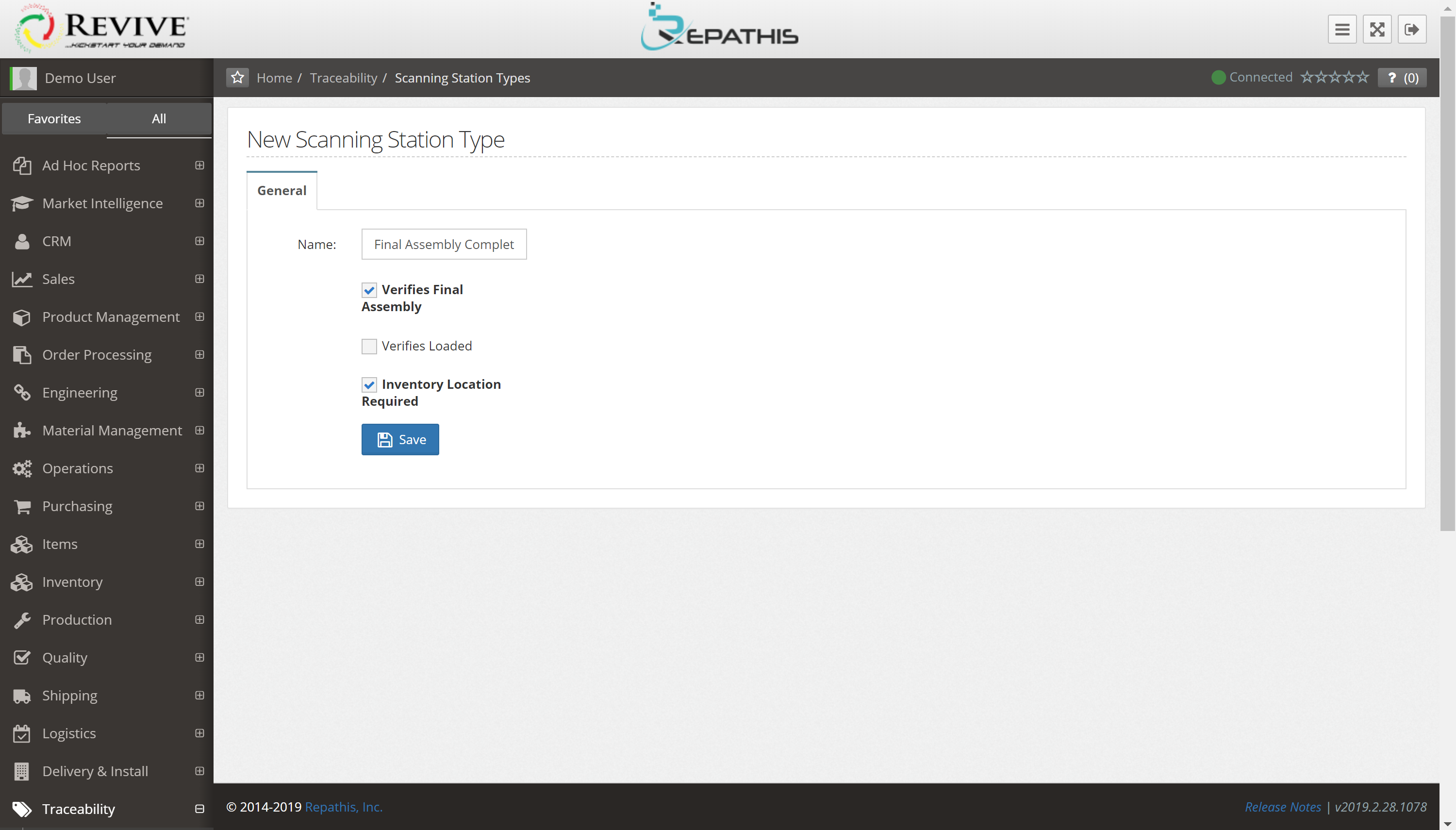

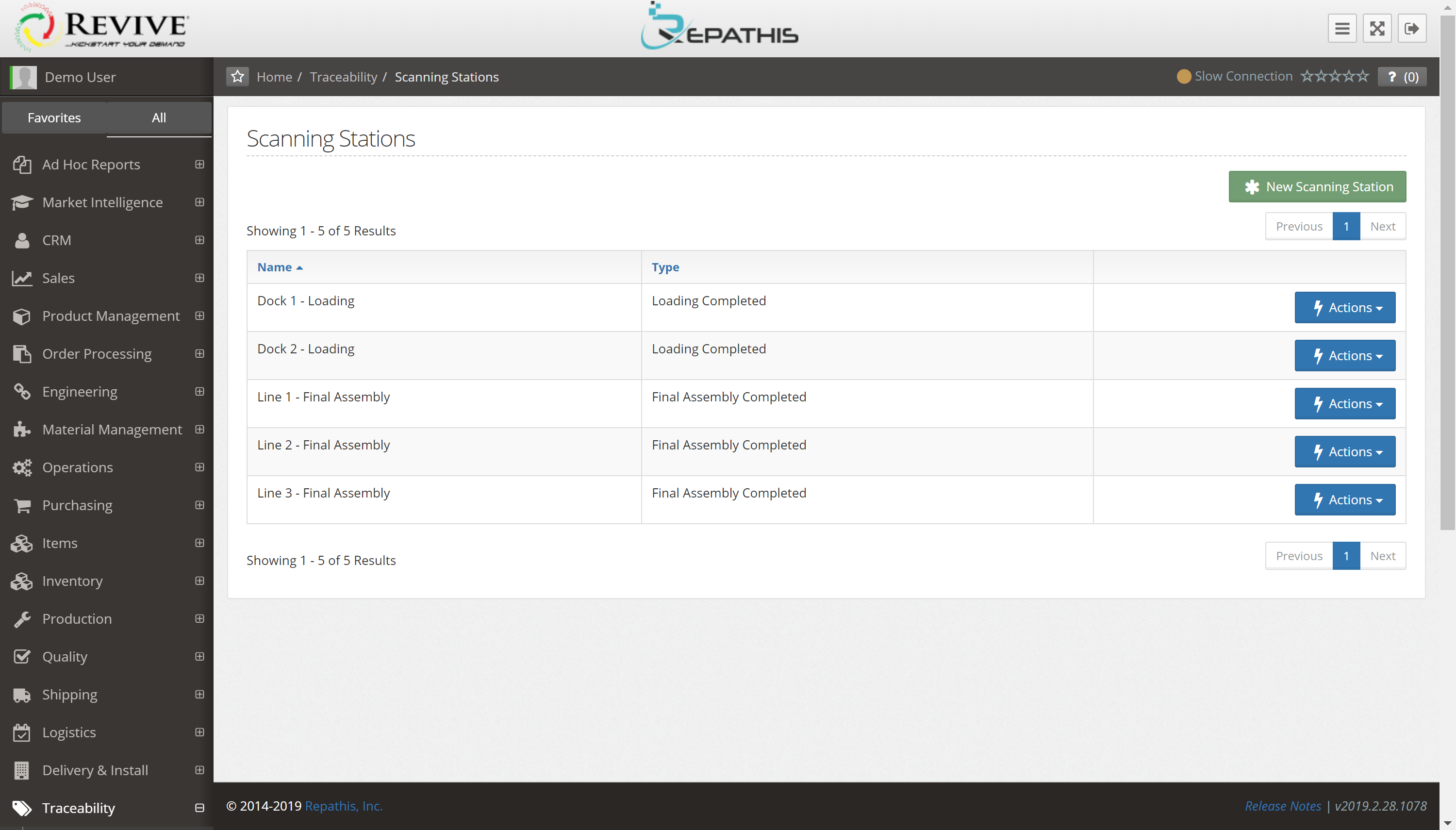

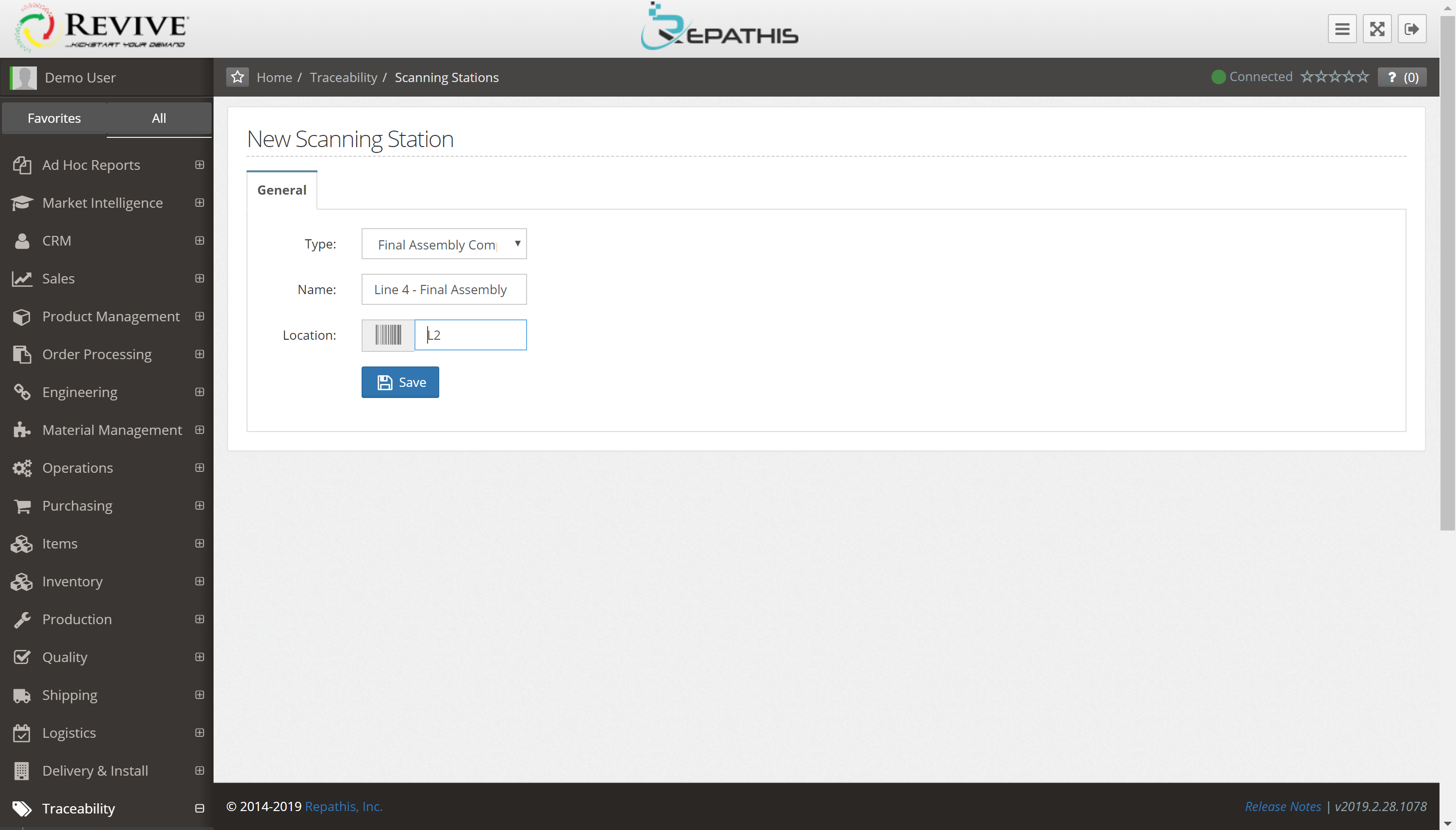

In the Scanning Station Types feature, it is simple to create different types of scanning stations and decide what kind information that type requires for set up or what kind of information it validates when a tag is scanned at that station. From there, you can easily set up various scanning stations in the Scanning Stations feature that fit into those types. These stations can represent different points in a process or different locations where collection of information is imperative, such as final assembly or inventory locations. When employees scan tags at these locations, relevant information will be automatically recorded to make tracking orders and information a breeze.

- Create different scanning station types that validate different information

- Set up various tag scanning stations at different locations or steps in a product or order’s journey

- Ensure that information and/or progress is recorded at imperative points in a process

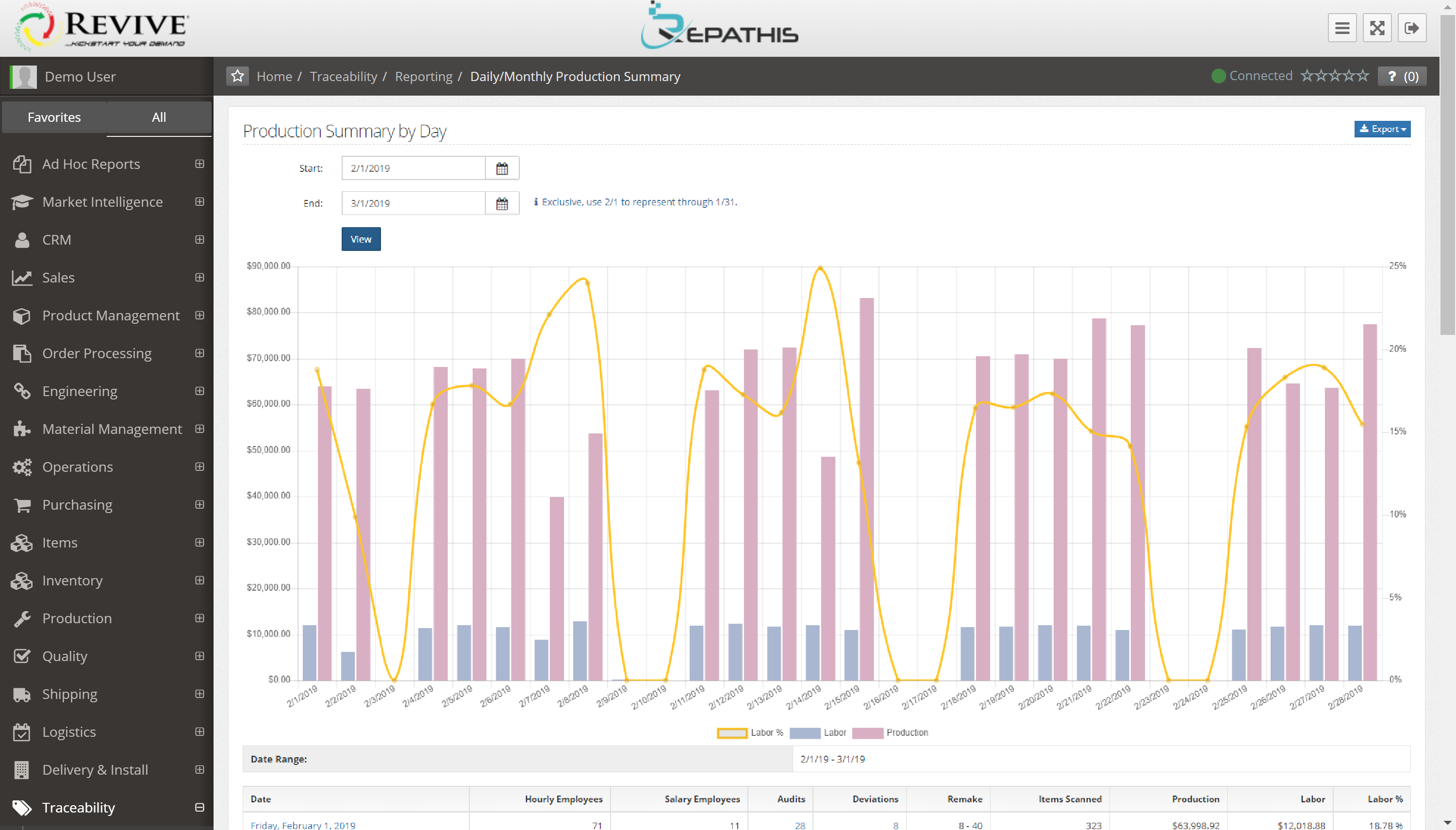

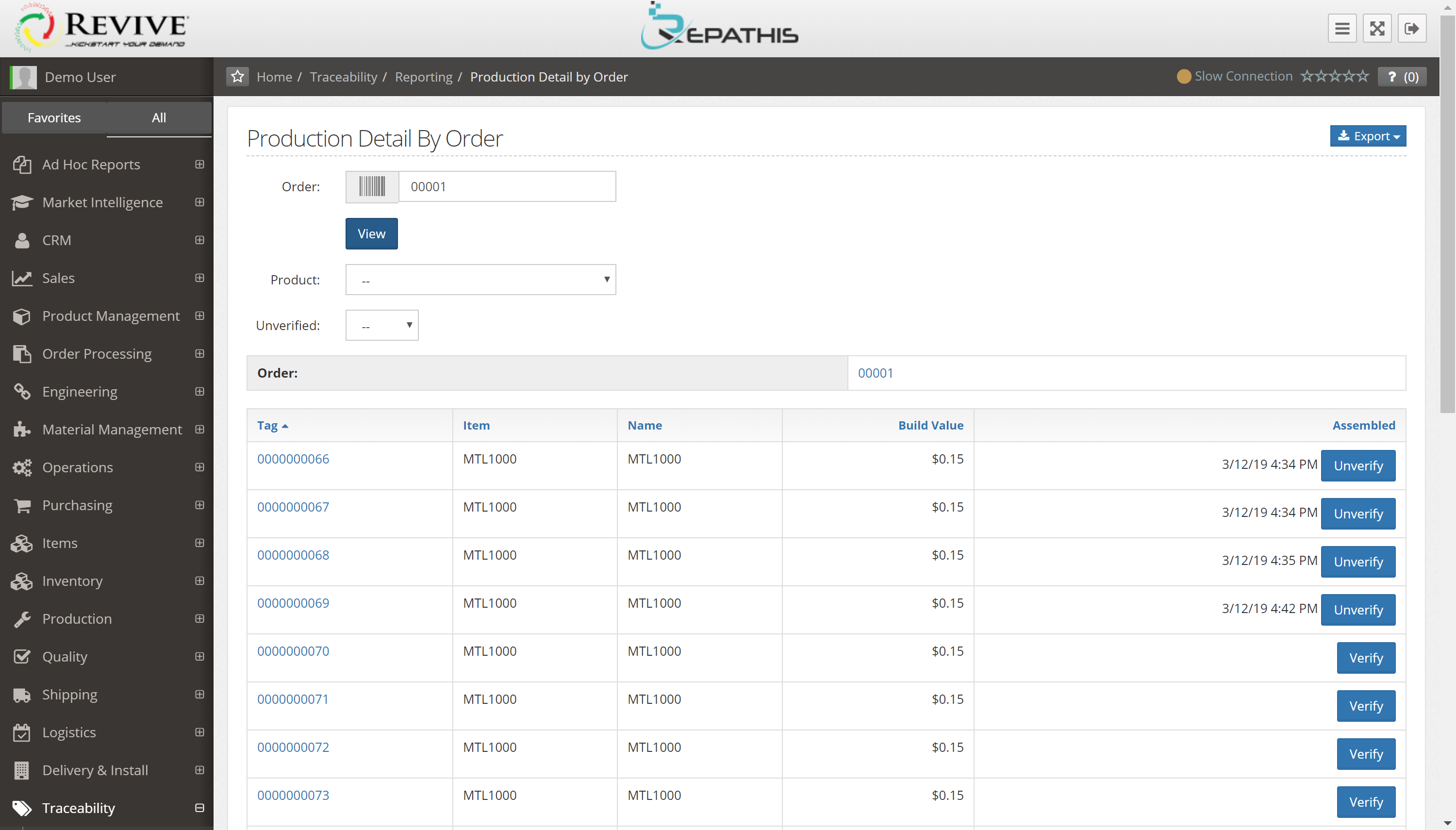

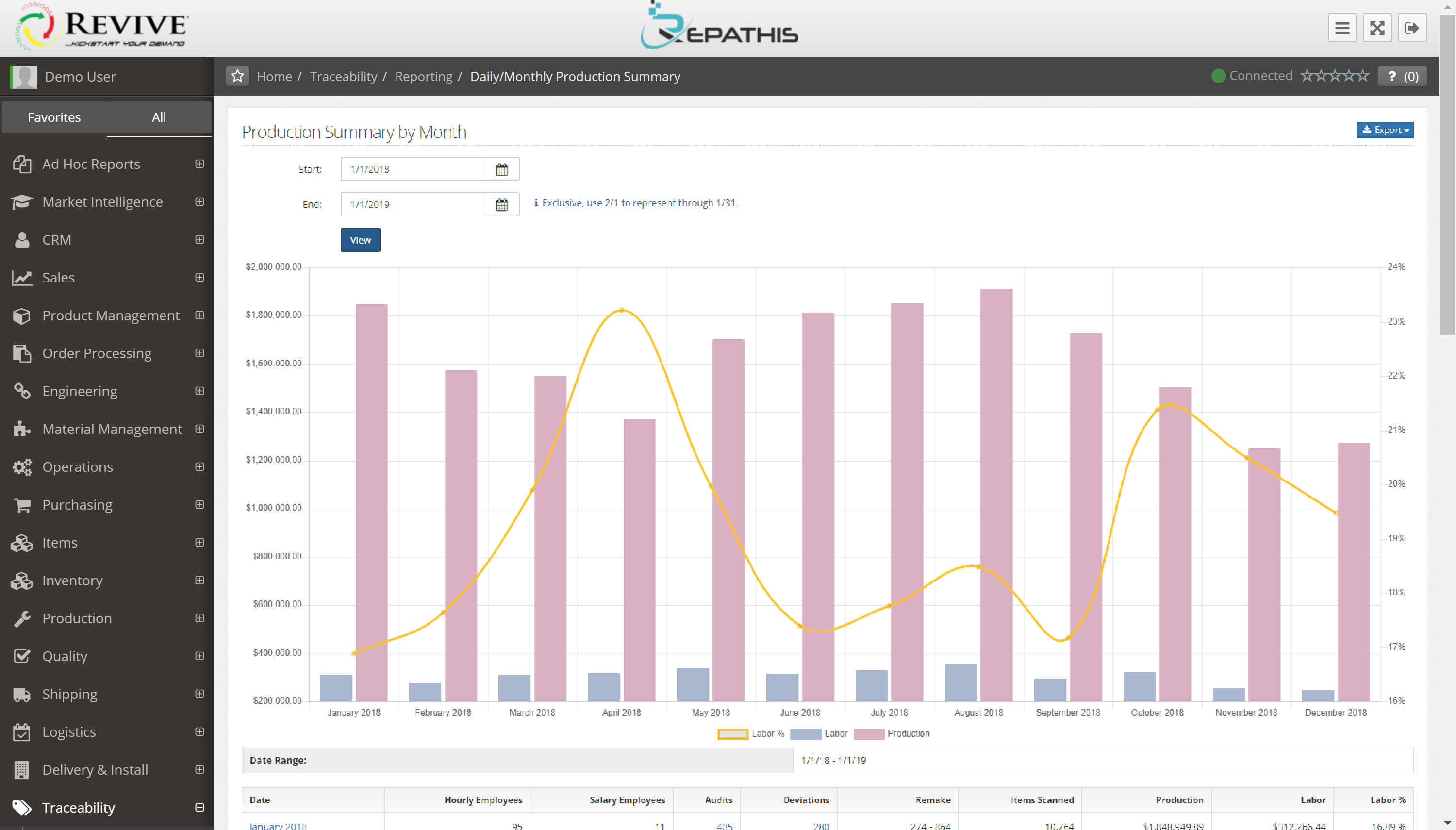

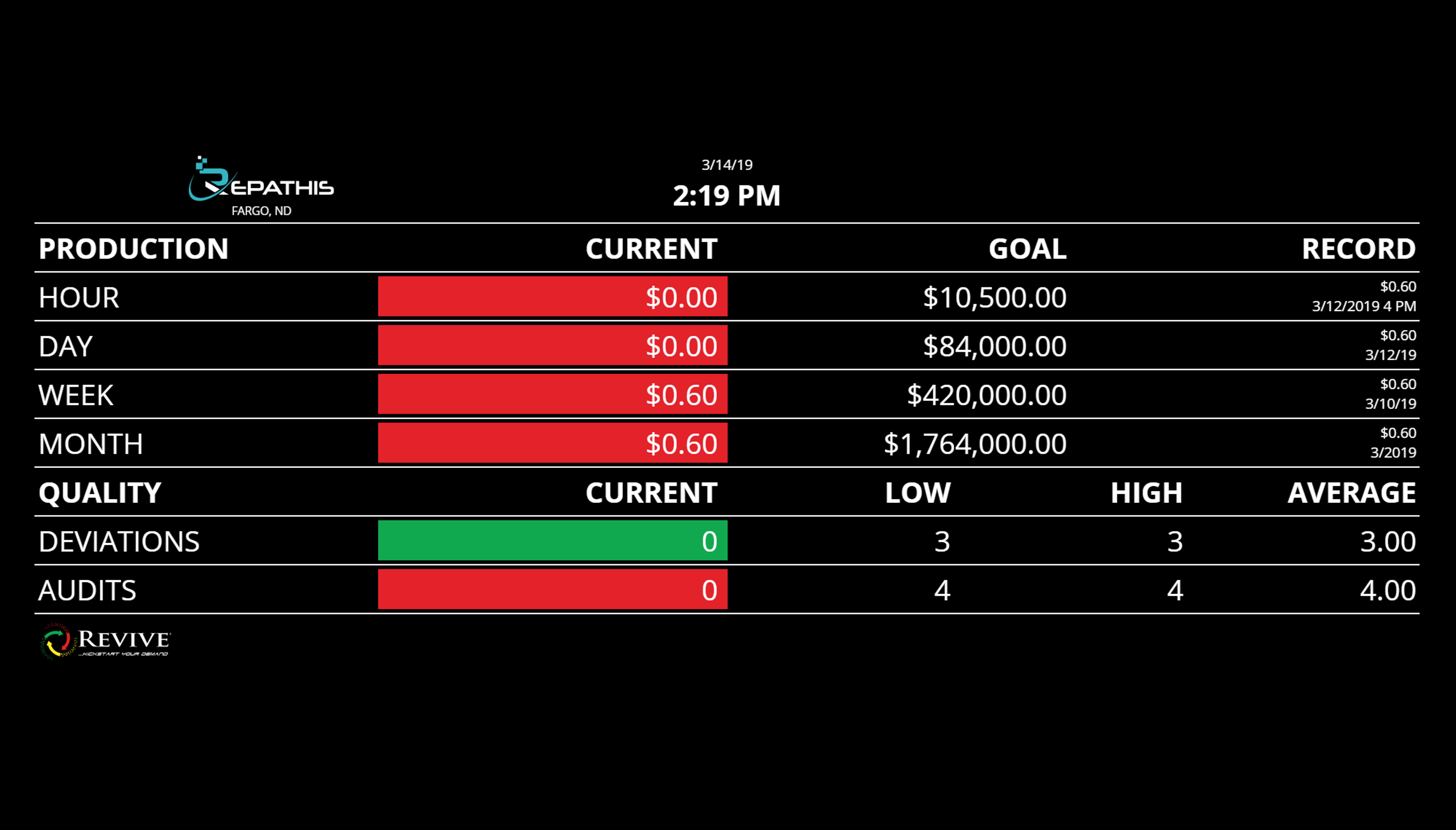

REPORTING

Generate a variety of reports to provide information and insights regarding orders, production statistics, and tags.

- Production Dashboard

- Completed Orders

- Production Detail by Date

- Production Detail by Order

- Daily Production Summary

- Production Summary

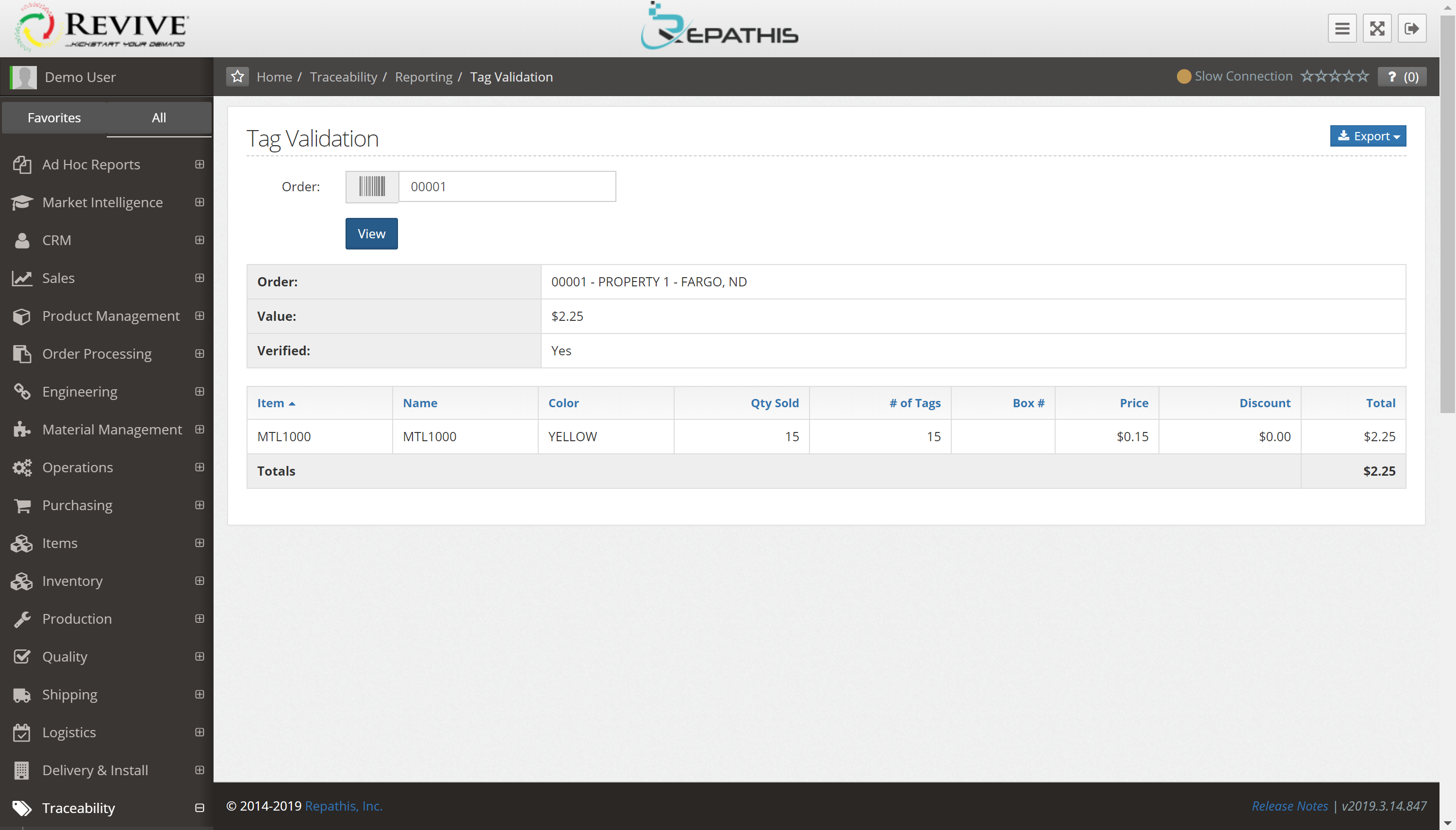

- Tag Validation

- Daily/Monthly Production Summary

- Monthly/Yearly Production Summary

- Orders without Tags

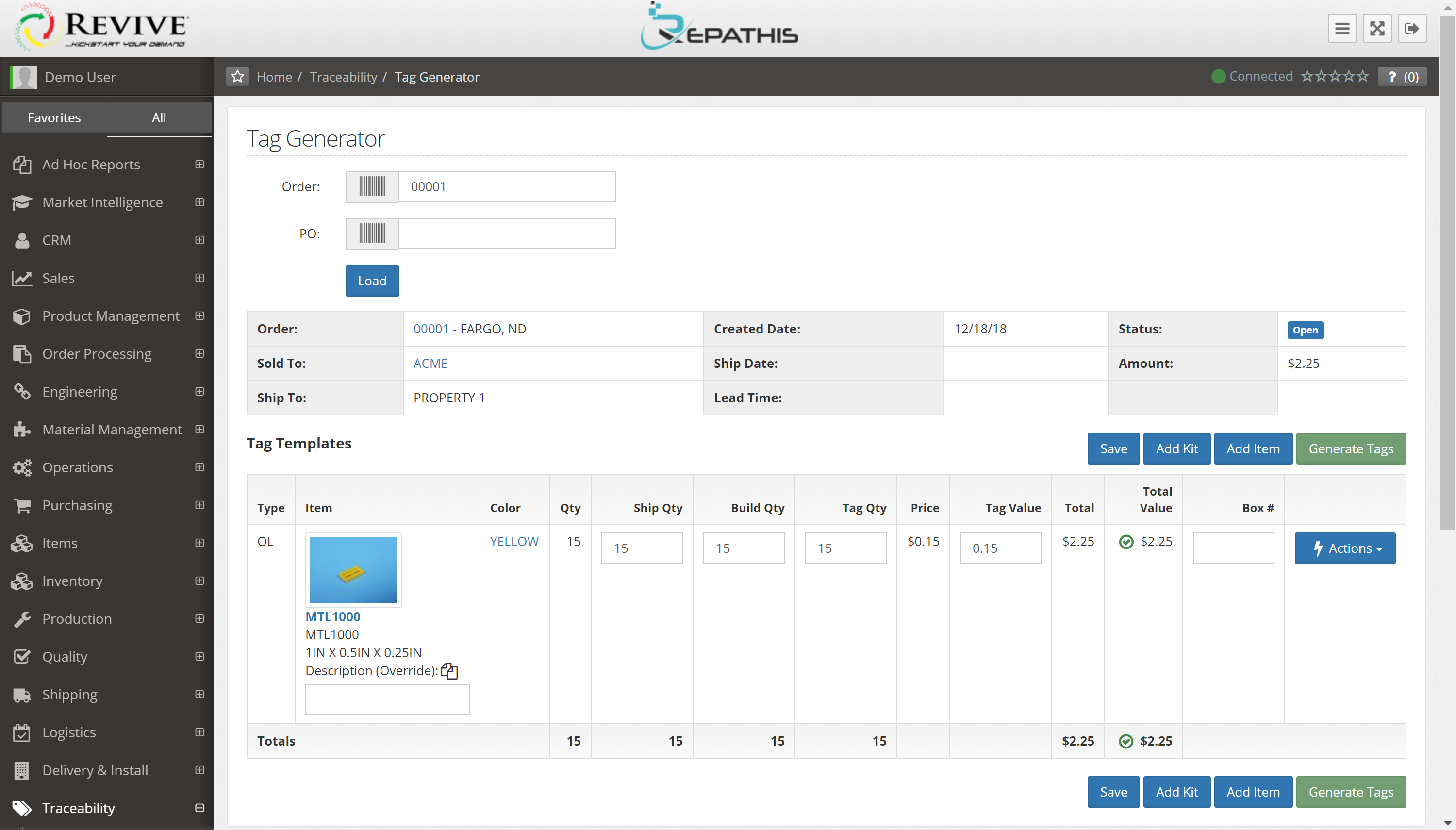

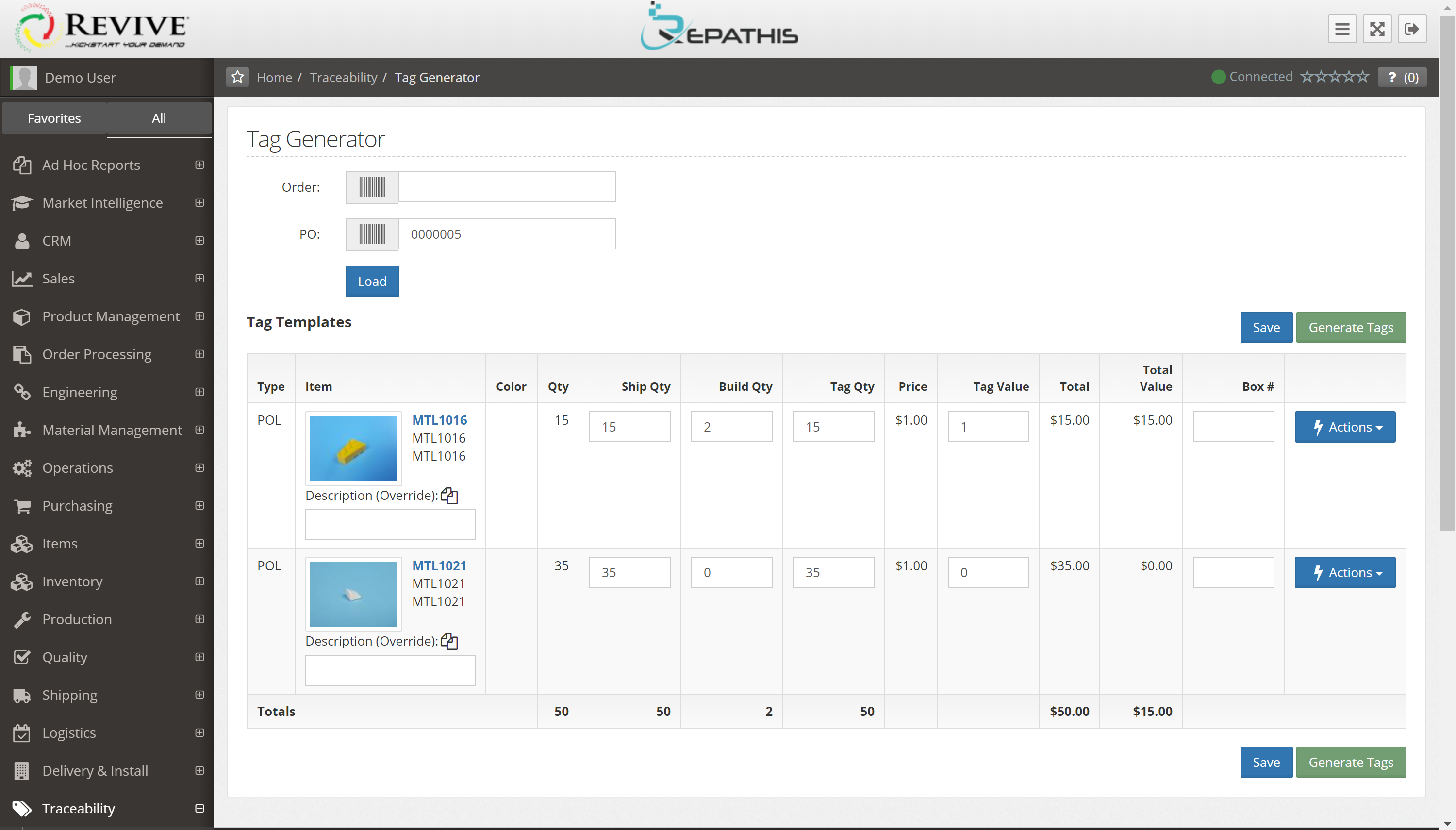

TAG GENERATOR

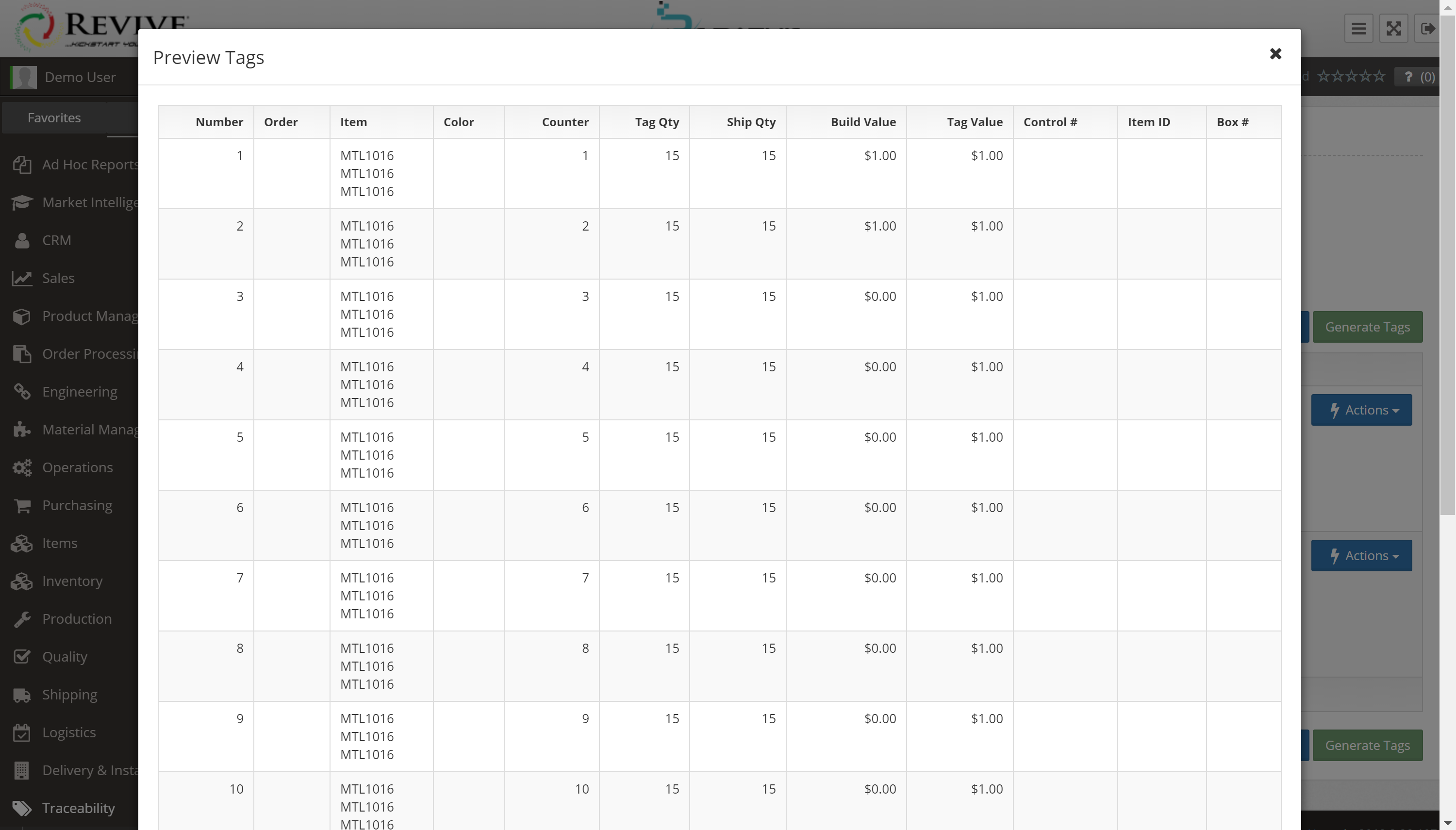

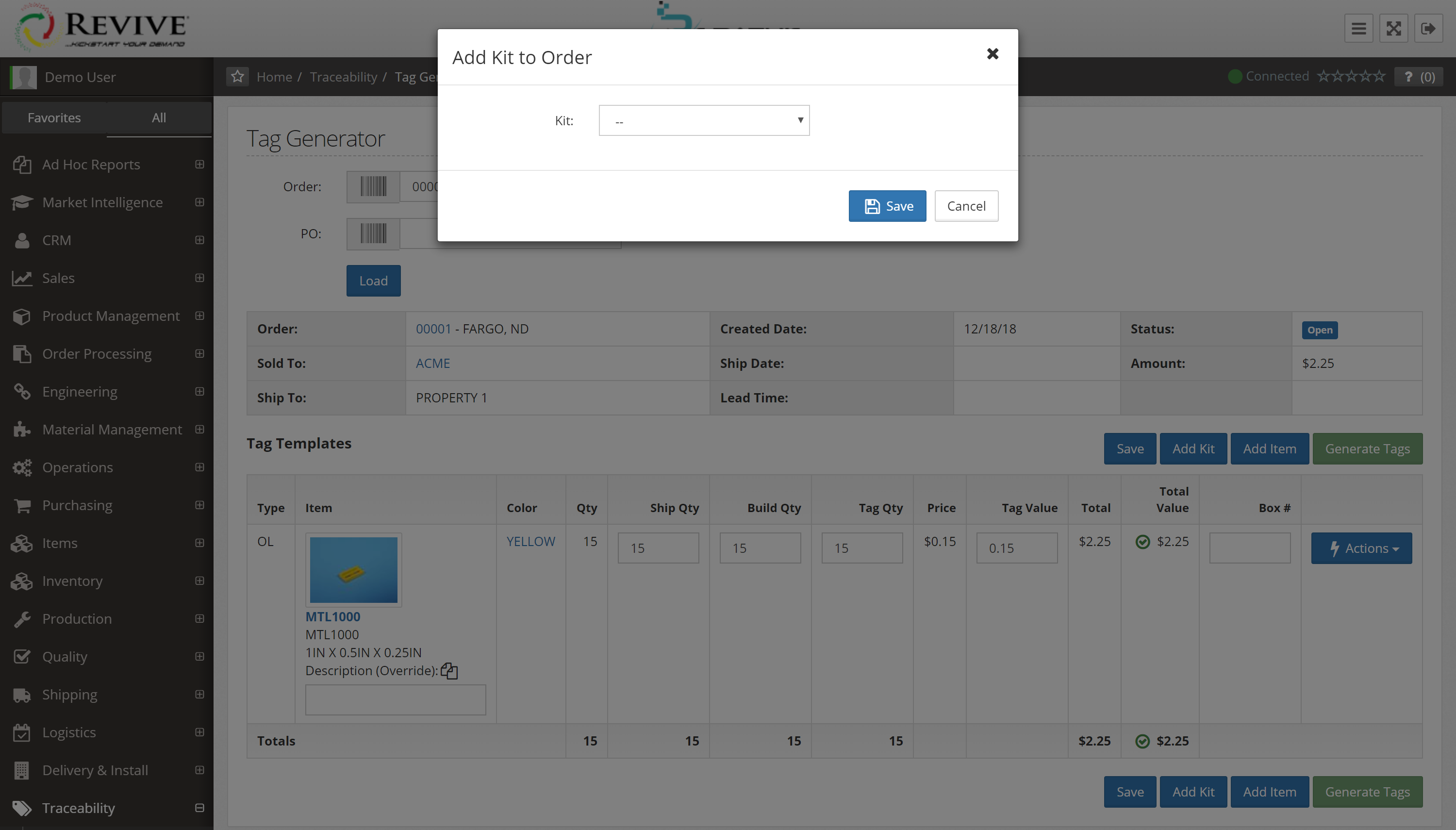

The Tag Generator feature works seamlessly with the Order Processing and Purchasing Modules to import item information from orders and purchase orders to create item tags. Searching or scanning an order or PO will pull up all line items for that order. You can then input information including ship quantity, build quantity, tag quantity, and tag value, allowing you to compare to the order or PO values. The system also calculates a total value based on the information inputted and compares that to the total value of the order, presenting an error message if the values do not align. Supplemental items or kits can also be easily added to the order at this point, and respective tags included. Once all information is correctly logged and the order is ready, all tags for the order can be previewed and generated with a click of your mouse. The Tag Generator feature can work with various label printers to produce tags.

- Search by order or PO to pull up tag templates and generate tags for each item included

- Tag templates include editable information fields such as ship quantity, build quantity, tag quantity, and tag value, allowing you to compare to the order or PO values

- Supplemental items or kits can be added to the order and tags

- Easily preview and generate tags for all items in the order or PO

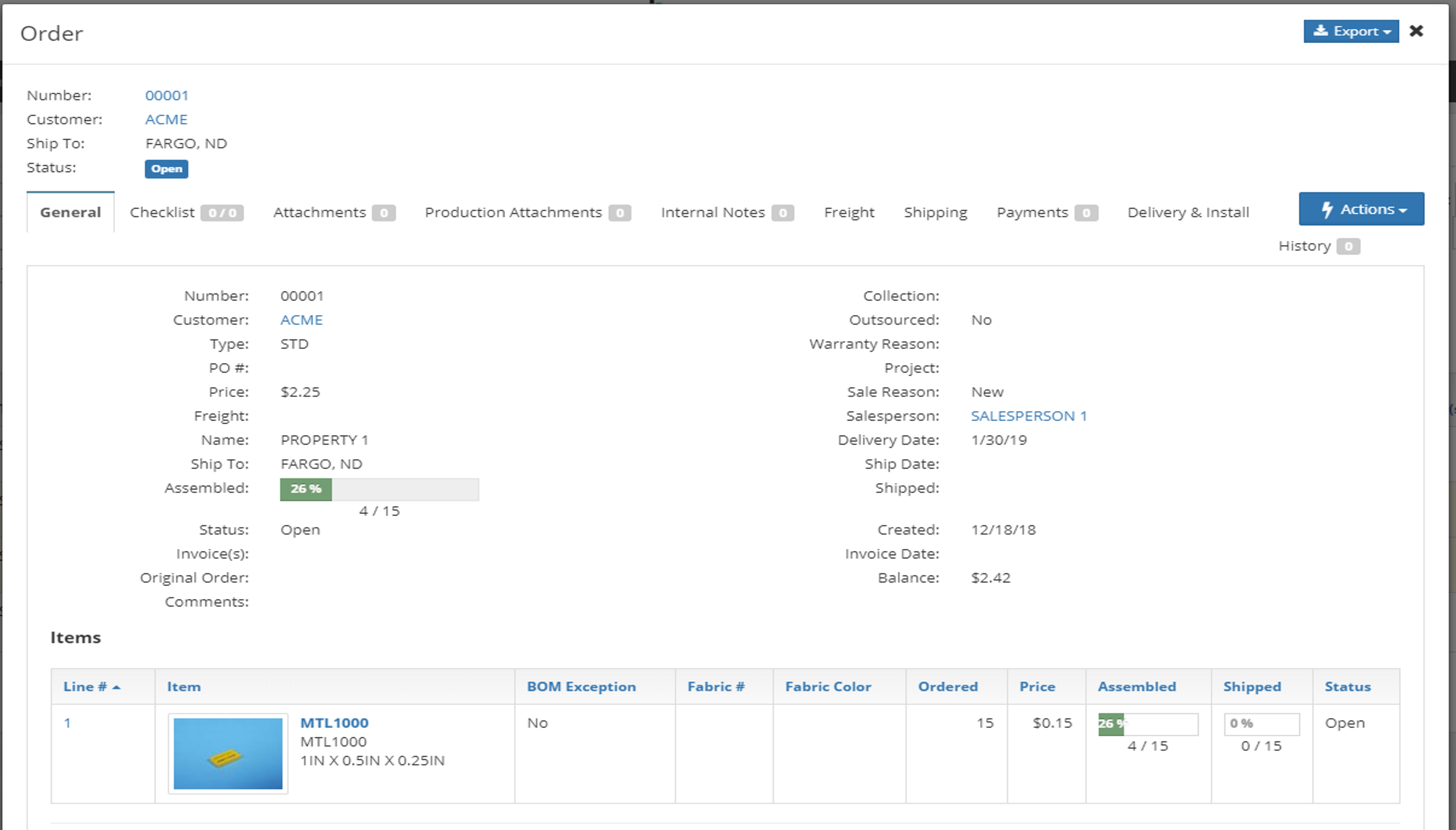

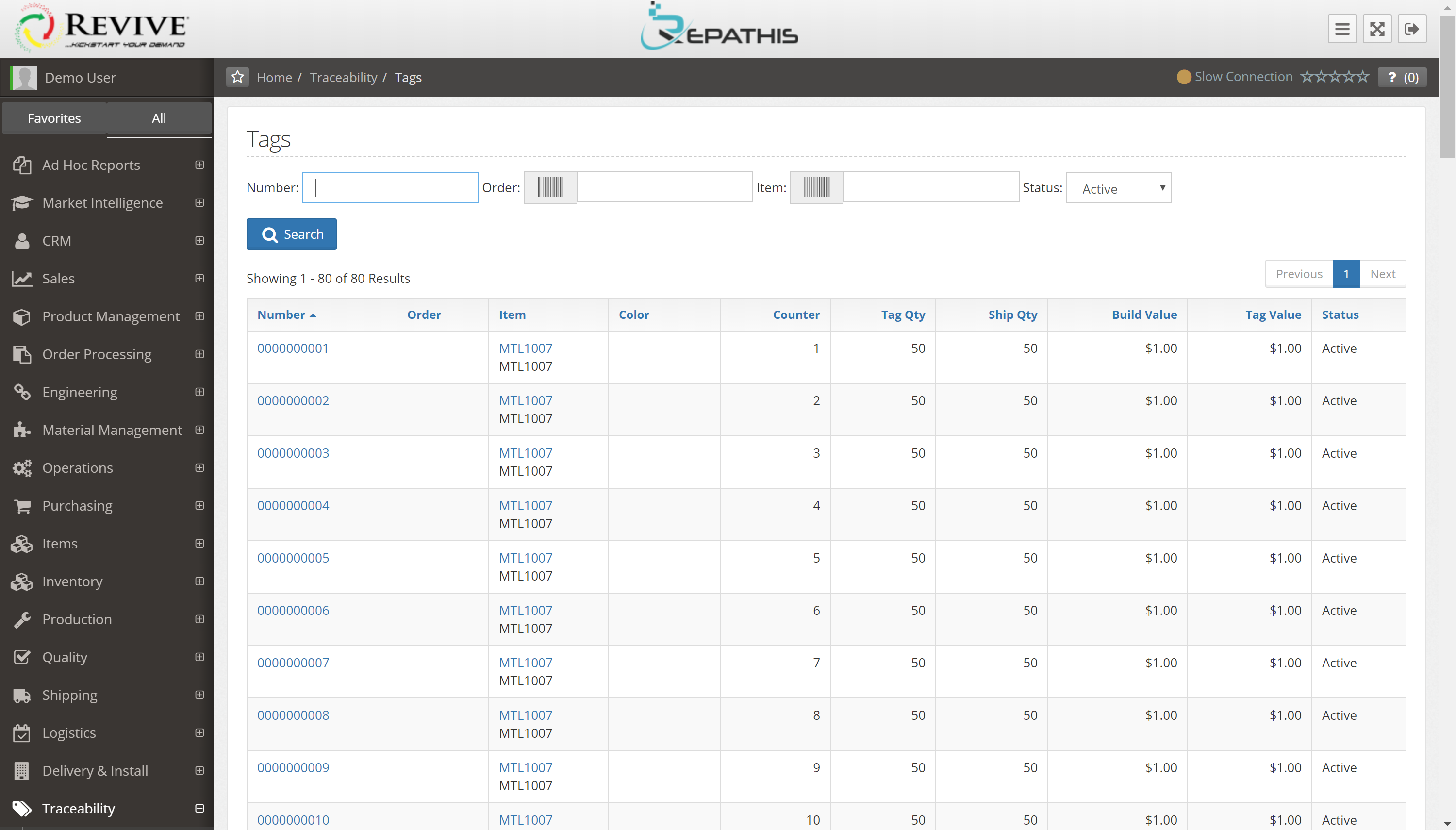

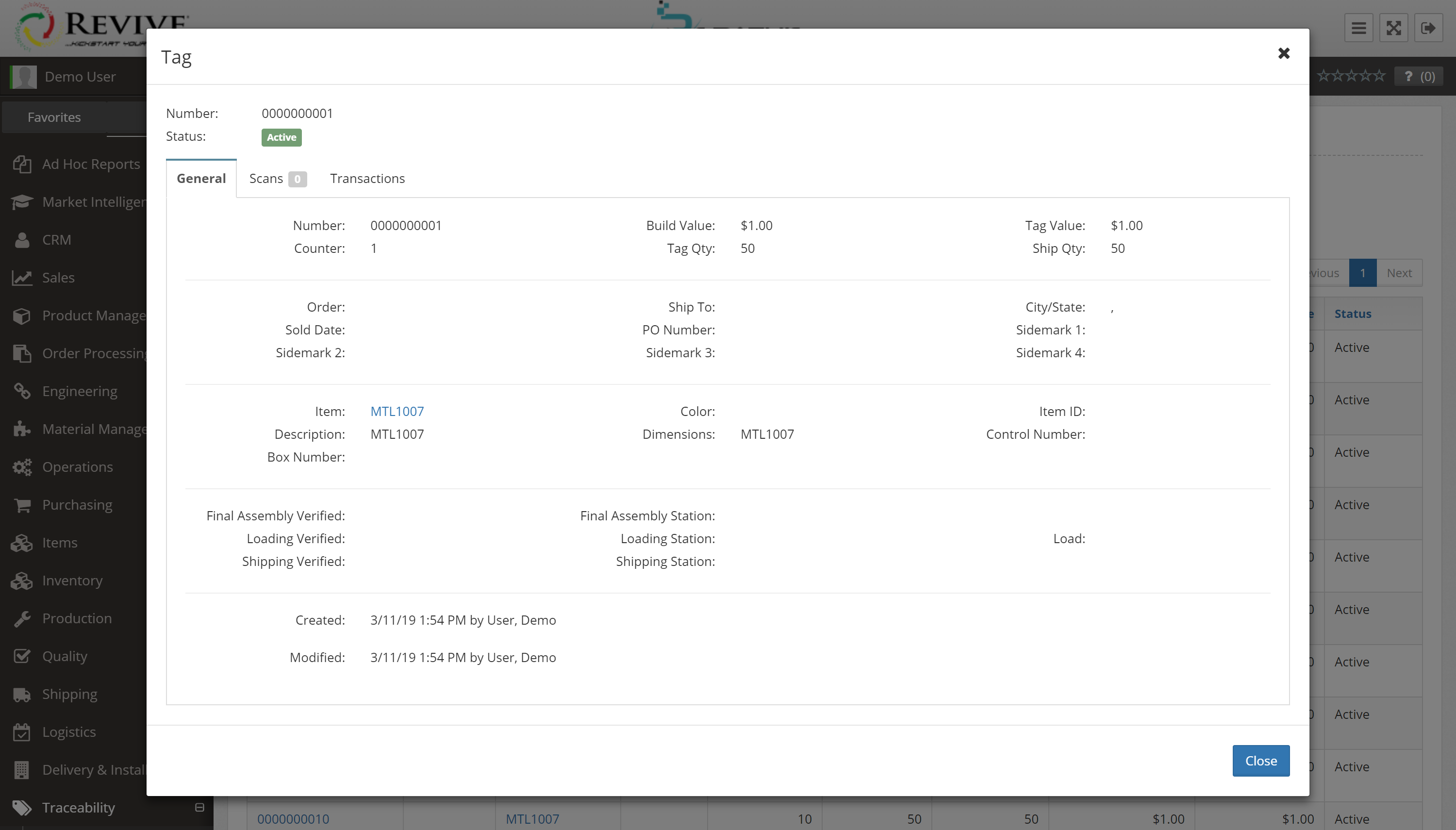

TAGS

Tags allow you to track finished goods and orders once complete. After generating tags for an order, they can be easily attached during final assembly and scanned directly after to mark the order as complete. Scanning will record relevant information such as where and when assembly took place and pricing, which will funnel into reporting. It will also update the order status in the Order Processing Module and update dollar amounts in the Production/Assembly Dashboard in the Production Module. As the finished good or order moves through inventory or shipping, it can be scanned at each point to track its movement and status, allowing for complete knowledge of where your goods are and access to real-time data when communicating with customers about their orders.

- Scan tags to mark products or orders as complete and record useful information

- Tags allow tracking of finished goods and orders once completed, whether through inventory or through shipping

- Scanning tags records important information and funnels relevant data to other modules